Effect of Red Pepper (Capsicum frutescens) Powder or Red Pepper Pigment on the Performance and Egg Yolk Color of Laying Hens

Article information

Abstract

Two experiments were conducted to study the effects of red pepper (Capsicum frutescens) powder or red pepper pigment on the performance and egg yolk color of laying hens. In Exp. 1, 210, thirty-wk old, Hy-line Brown laying hens were fed one of seven diets containing 0.3, 0.6, 1.2, 2.0, 4.8 or 9.6 ppm red pepper pigment or 0.3 ppm carophyll red. Each diet was fed to three replicate batteries of hens with each battery consisting of a row of five cages of hens with two hens per cage (n = 3). In Exp. 2, 180, thirty-wk old, Hyline Brown laying hens, housed similarly to those in Exp. 1, were fed an unsupplemented basal diet as well as treatments in which the basal diet was supplemented with 0.8% red pepper powder processed in a laboratory blender to an average particle size of 300 μm, 0.8% red pepper powder processed as a super fine powder with a vibrational mill (44 μm) and finally 0.8% red pepper powder processed as a super fine powder with a vibrational mill but mixed with 5% Na2CO3 either before or after grinding. A diet supplemented with 0.3 ppm carophyll red pigment was also included (n = 3). In both experiments, hens were fed the red pepper powder or pigment for 14 days. After feeding of the powder or pigment was terminated, all hens were fed the basal diet for eight more days to determine if the dietary treatments had any residual effects. In Exp. 1, there were no differences in egg-laying performance, feed consumption or feed conversion ratio due to inclusion of red pepper pigment in the diet. Average egg weight was higher (p<0.05) for birds fed 1.2, 2.4 or 9.6 ppm red pepper pigment than for birds fed the diet containing 0.3 ppm red pepper pigment. On d 14, egg color scores increased linearly as the level of red pepper pigment in the diet increased. In Exp. 2, feeding red pepper powder did not affect egg-laying performance, feed consumption or feed conversion ratio (p>0.05). However, compared with the control group, supplementation with all of the red pepper powder treatments increased egg weight (p<0.05). All the red pepper powder treatments also increased (p<0.05) the yolk color score compared with the control. The results of the present study suggest that both red pepper powder and pigment are effective feed additives for improving egg yolk color for laying hens.

INTRODUCTION

Egg yolk color is an important purchasing criterion for consumers (Esfahani-Mashhour et al., 2009) but the exact color desired varies among and within countries, with yellow to golden colors usually considered as the most attractive (Baiao et al., 1999; Rowghani et al., 2006). Carotenoids are a source of red and yellow pigments which alter egg yolk color (Baiao et al., 1999; Blount et al., 2000). Birds can’t synthesize these carotenoids and therefore they must be obtained from the diet from ingredients such as red pepper, pine and corn meal (Blount et al., 2000).

The red pepper is a good egg yolk colorant and is widely cultivated around the world (Şamlı et al., 2005; Barbero et al., 2008; Al-Kassie et al., 2011). The red pepper contains small amounts of red pigments and comparatively large amounts of yellow carotenoids which pass readily into the yolk thereby enhancing the intensity of the yellow color (Hamilton et al., 1990; González et al., 1999). Feeding red pepper to poultry does not appear to have any negative effects on productivity parameters (Furuse et al., 1994; Gurbuz et al., 2003; Rowghani et al., 2006).

Extraction of the pigments from the red pepper is relatively difficult involving lengthy extraction periods at high temperatures, requirements for hazardous organic solvents, expensive equipment (Huie, 2002), strong analyte-matrix interactions and high energy demands (Boldyrev and Tkáčová, 2000; Santos-Bocanegra et al., 2004; Carvalho et al., 2008). The development of an environmental friendly technique which would allow the egg yolk coloring ability of red peppers to be obtained at a lower cost with enhanced efficiency could be extremely beneficial to the poultry industry.

Previous work in our laboratory indicated that mechanochemical pretreatment significantly increased the yield of bioactive compounds from two herbs, Eleutherococcus senticosus and Crataegus pinnatifida (Liu et al., 2007). One of the key steps in this process was the production of a superfine powdered plant material. A further refinement was the procedure of grinding raw plant material in the presence of a solid reagent, a process known as mechanochemical treatment, which combines increased total contact surface area with destruction of the plant’s cell wall (Liu et al., 2007).

Sodium bicarbonate has been effectively utilized as a means of increasing the release of bioactive compounds in plants by neutralizing acidic constituents and increasing their solubility (Korolev et al., 2003, Liu et al., 2007). Capsanthin, which is presumed to be the major active constituent of red pepper, has an acidic hydroxyl group on its aromatic ring which could be neutralized by alkali thereby increasing its release (Liu, 2009).

The process of mechanochemical treatment has not been applied to red peppers. Therefore, an experiment was conducted to compare normal grinding and superfine grinding of red pepper with and without mechanochemical assisted extraction on the production performance and egg yolk color for laying hens. A second experiment was conducted to determine the effects of red pepper pigment on these same parameters.

MATERIALS AND METHODS

Acquisition of peppers and pigments

The red pepper pigment (color value = 150) was obtained from the Quzhou Red Chilli Factory (Hebei, China) and is marketed under the brand name of Red Chillies. It is a liquid product containing red pepper pigments mixed with plant oils. The carophyll red pigment (Carophyll Red 10%) was obtained from DSM Nutritional Products Ltd. (Basel, Switzerland) and contained 10% of the red-pigment carotenoid canthaxanthin. Analytical grade Na2CO3 was purchased from Tianjin Siyou Biomedical Technology Company (Tianjin, China).

The red pepper (Capsicum frutescens) used for the production of red pepper powder was purchased from a local agriculture market (Dalian, China), ground in a laboratory blender (Model FW177, Tianjin Taisite Instrument Company, Tianjin, China) to an average article size of 300 μm and stored at room temperature (20±3°C) until needed. In this manuscript, this product is referred to as normally processed red pepper powder.

The red pepper powder was additionally pre-treated in three ways for use in the experiment. The first treatment involved super fine grinding using a vibrational mill (Model WZJ (BFM)-6J; Billionpowder Tech & Engineering Company, Jinan, China) equipped with a water-cooled drum (drum volume: 1.2 L) and using steel rods as grinding bodies (18 mm diameter, 174 mm length). The mass ratio of the milling bodies to load weight was 100:1. The treatment produced red pepper powder with an average particle size of 44 μm. The second treatment involved super fine grinding as above, but the red pepper powder was hand mixed with 5% Na2CO3 (w/w) after grinding. The final treatment involved super fine grinding but 5% Na2CO3 (w/w) was added prior to grinding in the vibrational mill.

The morphology of the powder obtained from the different pretreatments was examined using scanning electron microscopy (JEM-1200EX, equipped with a scanning image device, JEOL Co. Ltd., Tokyo, Japan). Samples were mounted on metal stubs, using double sided adhesive tape, gold coated under vacuum and then examined under high-vacuum conditions with an accelerating voltage of 40 kV.

Sample particle size was determined using standard sieves (ISO3310-1:1990, R40/3, Xinxiang Kangdaxin Machinery Co., Ltd., Xinxiang, China) and a Laser Diffraction Particle Analyzer (LS100 Q, Beckman Coulter Inc., Fullerton, CA, USA).

Performance trials

Exp. 1 was conducted with 30-wk old Hy-line Brown (n = 210, initial body weight of 1.70±0.23 kg) laying hens which were obtained from the Liu Family Chicken Farm located in Dalian, China. The hens were fed a corn-soybean meal basal diet (Table 1) which was purchased from the Hefong Feed Mill (Dalian, China). The treatments consisted of a control group which was fed the basal diet supplemented with 0.3 ppm carophyll red as well as six treatment groups which were supplemented with 0.3, 0.6, 1.2, 2.4, 4.8 or 9.6 ppm red pepper pigment (Quzhou Red Chilli Factory, Hebei, China). Each treatment was fed to three replicate batteries of hens with each battery consisting of a row of five cages of hens with two hens per cage.

Exp. 2 was performed with 30-wk old Hyline Brown (n = 180, initial body weight of 1.76±0.12 kg) laying hens obtained from the same source as those used in Exp. 1 and fed a similar diet prior to the initiation of the experiment. The hens were fed one of six dietary treatments which consisted of an unsupplemented corn-soybean meal basal diet as well as treatments in which the basal diet was supplemented with 0.8% of normally processed red pepper powder (average particle size of 300 μm), red pepper processed as a superfine powder with a vibrational mill (average particle size of 44 μm) and finally red pepper processed as a superfine powder with a vibrational mill but mixed with 5% Na2CO3 either before or after grinding. The sixth treatment was the basal diet supplemented with 0.3 ppm carophyll red pigment.

For both experiments, the hens were fed the basal layer diet with no additives for the first week to allow them to adapt to their new environment. The hens were then fed diets containing the red pepper powder or pigments for 14 d. After the experimental period, all hens were given the basal diet for eight more days to determine if the dietary treatments had any residual effects.

Eggs were collected daily each morning. Egg production levels, egg weights and daily feed consumption of the hens were determined daily. Feed conversion ratio was calculated according to feed consumption per kg of egg produced. Five eggs from each row were chosen at random for yolk color measurement on the 7th and 14th days of the experiment and also 8 d after provision of the feed additives was discontinued. An Ovo-Color Yolk Color Fan supplied by BASF (Florham Park, NJ, USA) was used to subjectively measure yolk color with heavy white paper placed underneath the fan as a neutral background following the procedures of Vuilleumier (1969).

Statistical analysis

Statistical analysis was performed using SPSS for Windows (SPSS, 2004). All values are expressed as their mean±standard deviation (SD) and levels of significance were evaluated using a one-way ANOVA followed by Student-Neuman-Keuls test for multiple comparisons. Differences were considered significant at the level of p<0.05.

RESULTS AND DISCUSSION

In Exp. 1, there were no significant differences observed for egg-laying performance, feed consumption or feed conversion ratio (p>0.05) due to inclusion of red pepper pigment in the diet (Table 2). These findings agree with those of Gurbuz et al. (2003) and Şamlı et al. (2005). Average egg weight was significantly higher for birds fed the diets containing 1.2, 2.4 or 9.6 ppm red pepper pigment compared with birds fed the diet containing 0.3 ppm red pepper pigment. A beneficial effect of red pepper pigment on egg weight has not been previously reported and an explanation for this increase is not readily available.

Color scores were increased in a linear fashion by increasing dietary red pepper pigment (Table 3). On d 14, including 4.8 or 9.6 ppm red pepper pigment produced similar egg yolk color scores as did 0.3 ppm carophyll red (p>0.05) while lower color scores were obtained for 0.3, 0.6, 1.2 and 2.4 ppm red pepper pigment (p<0.05) indicating that red pepper pigments are not metabolized as effectively as the dye carophyll red. However, artificial color additives have been suggested to have cancerous side effects and therefore it is safer to utilize the natural color additive in red pepper pigment to improve yolk pigmentation in place of artificial additives (Gurbuz et al., 2003).

Significant increases in egg yolk color scores were observed as early as 7 d following the incorporation of red pepper pigments in the diet. In addition, it would appear that red pepper pigments continue to alter egg yolk color scores following their removal from the diet as, at the highest inclusion level (9.6 ppm), there was still a significant residual effect seen eight days after withdrawal of the pigment from the diet. It is interesting to note that the residual effect of 9.6 ppm red pepper pigment was greater than that of 0.3 ppm carophyll red.

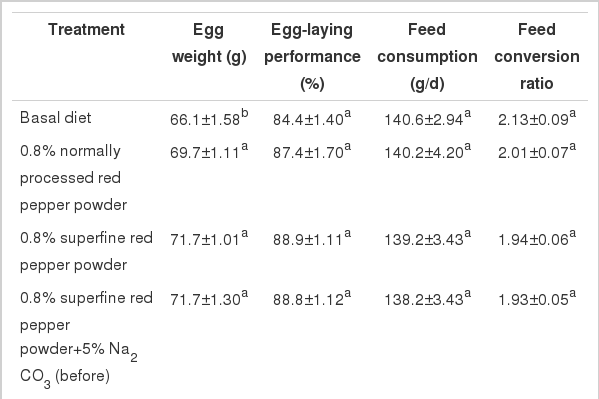

Exp. 2 studied the effects of various processing methods for red pepper powder on the performance of laying hens and their egg yolk color scores. The egg-laying performance and average egg weight of hens fed red pepper powder is presented in Table 4. The performance of birds fed the carophyll red diet did not differ from that of birds fed the basal diet (p>0.05). In addition, there were no significant differences between birds fed the basal diet and birds fed any of the red pepper powder treatments for egg-laying performance, feed consumption or feed conversion ratio (p>0.05). This agrees with previous research (Gurbuz et al., 2003; Rowghani et al., 2006). However, compared with the basal diet, all the red pepper powder treatments significantly (p<0.05) increased egg weight. An explanation for this effect is not immediately obvious. However, carotenoids are a precursor for vitamin A. Under normal conditions, supplementation of vitamin A above NRC (1994) recommendations has no effect on the performance of laying hens. However, under conditions of heat stress, supplementation with additional vitamin A has been shown to improve laying hen performance and egg weight (Lin et al., 2002). The current experiment was conducted in August and the birds might have been subjected to mild heat stress thus explaining the increase in egg weight due to supplementation with red pepper powder.

The effects of feeding red pepper powder on egg yolk color scores are presented in Table 5. On both d 7 and 14, all the red pepper powder treatments darkened (p<0.05) the color score compared with birds fed the basal diet. Super fine grinding produced a higher color score than normal processing (p<0.05). However, the inclusion of 5% Na2CO3 added either before or after grinding produced no further improvements in color score over that obtained with superfine grinding alone (p>0.05).

All red pepper powder treatments were successful in maintaining a higher egg yolk color score than that observed for birds fed the basal diet for at least eight days after being removed from the diet. The super fine grind treatments were superior to the normal grind treatment in this regard. In addition, the residual effect of the red pepper powder treatments was superior to that obtained for carophyll red.

The improvements in egg yolk color score for birds fed the superfine red pepper powder compared with those fed red pepper powder processed normally can be explained by examining the results of the electron microscope scan. In order to determine what alteration had been done to the cells during the processing used in the present experiment, red peppers produced by two of the treatments were examined by a scanning electron microscope (Figure 1). The structure of super fine ground red pepper powder are shown in comparison to that processed using a vibrational mill with the addition of Na2CO3 (after grinding).

SEM micrographs of Capsicum frutescens processed by different treatments. A = super fine ground red pepper powder (44 μm); B = super fine ground red pepper with 5% Na2CO3 added after grinding (44 μm).

The primary structures in the normally processed material ground in the laboratory blender were unaffected with a majority of intact cells and highly rough surfaces (average particle size of 300 μm). For the treatments involving the vibrational mill, no intact cells were observed, indicating that a complete breakup of the cell wall had occurred after the mechanical grinding.

The complete breakup of the cell wall due to superfine grinding would likely increase the ability of birds to access the pigments in the red pepper facilitating their uptake and incorporation into egg yolk. This theory is supported by previous work in our laboratory where superfine grinding significantly increased the yield of bioactive compounds from various herbs (Liu et al., 2007). In addition to breakdown of the cell wall, super fine grinding resulted in particles sizes of approximately 44 μm compared with particle sizes of 300 μm for normal grinding. A reduction in particle size increases surface area further enhancing the ability of laying hens to access the red pigments in the powder.

In the present experiment, the use of Na2CO3 before or after grinding did not appear to enhance the release of the pigments from the red pepper powder over that which was obtained with superfine grinding alone and therefore would not appear to be an effective addition to the production process for red pepper powder. Previous work in our laboratory indicated enhanced extraction of the active compound Isofraxidin from Eleutherococcus Senticocsus when Na2CO3 was added to a superfine powder (Liu et al., 2007). The difference in the effectiveness of Na2CO3 to facilitate extraction of the active components from the two plant sources may reflect differences in solubility between these compounds.

CONCLUSIONS

The results of the present experiments indicate that dietary inclusion of both red pepper powder and pigment were successful in increasing the egg yolk score of laying hens which would make these eggs more attractive to potential consumers. Neither product produced any negative effects on laying hen productivity and both products had a tendency to increase the weight of the eggs from treated hens.

The present study suggests that superfine grinding is superior to normal grinding for red pepper powder production as scanning electron microscopy indicated complete breakup of the cell wall structure of the red pepper with superfine grinding, while with normal grinding, many intact cells were still observed. Use of Na2CO3 before or after grinding did not have any beneficial effects on egg yolk color over that obtained with superfine grinding alone. Therefore, there would appear to be little justification for including it in the process to produce red pepper powder.

ACKNOWLEDGEMENTS

This work was financial supported by “863” Program, Hi-tech Research and Development Program of China (2006AA10Z412), the National Natural Science Foundation of China (31001053) and the National Outstanding Youth Foundation of China (30125034). The work was also partly supported by the National Innovation Fund for Small Technology-Based Firms of China (06C26222120113). The authors gratefully thank Professor Philip A. Thacker from the University of Saskatchewan for his valuable suggestions and for revising the manuscript.