Nutrient variations from swine manure to agricultural land

Article information

Abstract

Objective

Swine manure in Korea is separated into solid and liquid phases which are composted separately and then applied on land. The nutrient accumulation in soil has been a big issue in Korea but the basic investigation about nutrient input on arable land has not been achieved in detail. Within the nutrient production from livestock at the national level, most values are calculated by multiplication of the number of animals with the excreta unit per animal. However, the actual amount of nutrients from swine manure may be totally different with the nutrients applied to soil since livestock breeding systems are not the same with each country.

Methods

This study investigated 15 farms producing solid compost and 14 farms producing liquid compost. Composting for solid phase used the Turning+Aeration (TA) or Turning (T) only methods, while liquid phase aeration composting was achieved by continuous (CA), intermittent (IA), or no aeration (NA). Three scenarios were constructed for investigating solid compost: i) farm investigation, ii) reference study, and iii) theoretical P changes (ΔP = 0), whereas an experiment for water evaporation was conducted for analyzing liquid compost.

Results

In farm investigation, weight loss rates of 62% and 63% were obtained for TA and T, respectively, while evaporation rates for liquid compost were 8.75, 7.27, and 5.14 L/m2·d for CA, IA, and NA, respectively. Farm investigation provided with the combined nutrient load (solid+liquid) of VS, N, and P of 117.6, 7.2, and 2.7 kg/head·yr. Nutrient load calculated from farm investigation is about two times higher than the calculated with reference documents.

Conclusion

The nutrient loading coefficients from one swine (solid+liquid) were (volatile solids, 0.79; nitrogen, 0.53; phosphorus, 0.71) with nutrient loss of 21%, 47%, and 29%, respectively. The nutrient count from livestock manure using the excretion unit has probably been overestimated without consideration of the nutrient loss.

INTRODUCTION

Along with the economic growth, the consumption of pork has increased from 16.5 kg/person in 2000 to 20.9 kg/person in 2013 and swine farms have become industrialized, which resulted in an increase of the number of swine per farm from 342 in 2000 to 1,652 in 2013 [1]. Increasing the number of swine inevitably accompanies an increment of manure production, whereby livestock farms have been confronted with many difficulties such as malodor, manure treatment, and epidemic diseases.

The morphological characteristics of swine excreta may have variation by the types of excreta collecting structure. The average volume of excreta per head was reported with 2.61 L/d including urine by Ministry of Environment (ME) in Korea Since swine manure contains relatively high moisture content and additional water of 2.49 L/d is added for washing, its management is not straightforward to release or produce compost. Thus, most farms in Korea initially separate solid fraction from manure and produce solid and liquid compost [2].

Livestock manure contains high nutrients for crop growth and 88.7% of the entire manure from all the livestock categories was recycled to arable land in the form of compost in Korea, 2012 [1]. Composting is a core method of sustainable agriculture with respect to circulation of nutrients such as carbon, nitrogen (N), and phosphorus (P). Unfortunately, surplus nutrients over demand of crop growth may be accumulated on land and further released into water bodies causing eutrophication, as reported by the Korea Research Economic Institute (KREI) in 2004 [3].

In fact, looking over the mass balance within the boundary of land and animal breeding, the animal feeds are mostly coming from outside of the farm, then the nutrients in excreta can be over the demand of the crop growing near around the animal farm [4–6]. Adversely from trends of increasing manure production, the arable land of 2.11 million ha in 1990 has gradually decreased to 1.73 million ha in 2012 [7], which resulted in accumulation of surplus nutrients on arable land.

According to KREI (2013), the amounts of N and P applied on agricultural land were 380,000 and 150,000 tons, respectively, via both chemical fertilizer and livestock manure compost. Livestock manure compost contributes 31.6% and 40.0% for N and P, respectively [7].

However, no systematic study has been conducted about nutrient loading from livestock manure and calculation on site. In addition, such a result was calculated by multiplication of the number of livestock with the coefficients of excreta reported by ME. Compared to farm practices in other countries, the livestock manure management is much different in Korea due to livestock raising circumstances, such as regional climate and applicable arable land of compost from livestock manure. For instance, a farm having pasture is possibly applied with the calculation of nutrient loading on soil based on the coefficients of excreta per animal, whereas a farm having only barn with intensive raising may not be applicable with such a calculation. Since, the site of manure production is different with the one where the manure is applied, manure shall always be stored or treated in a composting lot and N (ammonia) content is volatilized and lost. Furthermore, the calculation of the nutrient balance is achieved through three ways in Organization for Economic Co-operation and Development (OECD); i.e., land, soil, and farm budget, but OECD mostly applies land budget since there are not enough data base for soil and farm budget. It would be appropriate to apply land budget method for countries where livestock grazing is applicable but Korea is not applicable for land budget because there is insufficient pasture for grazing and the sites of production and application for manure compost are mostly different. Manure from livestock is obliged to stay in composting lot in livestock farm. Therefore, raw manure without staying in lot cannot be applied to arable land, which makes the reason why land budget is not suitable for the calculation of manure nutrients in Korea. As per the explanation, the application site of compost from livestock manure is different from the production site of livestock manure. In order to manage livestock manure effectively and estimate actual values of nutrients on arable land under a given condition in Korea, building up database of nutrient loss between raw manure and compost is imperative through the direct investigation over a few years.

Hence, this study aimed to evaluate practical nutrient loading on arable land from fresh swine manure after composting period and calculate the loss of nutrients, i.e. volatile solids (VS), nitrogen (N), and phosphorus (P), during the management periods, which results in developing the coefficients considering the loss of nutrients and helps swine manure management and soil maintenance with respect to nutrient fluxes.

MATERIALS AND METHODS

Sample collection and farm investigation

In order to analyze the amount of nutrients from swine manure, total 29 farms were selected, which can be separated into two types; i.e., after solid and liquid separation, one produces compost in both solid and liquid phases and the other produces only solid compost of which the liquid fraction is treated in water treatment facilities to release to water bodies. Consequently, 15 farms conducting solid composting were selected those were using two types of methods for air supply either both Turning+Aeration (TA) or Turning (T) only by 5 and 10 farms respectively. There were 14 selected farms producing liquid compost by three types of aeration methods such as continuous, intermittent, and no aeration, used by 5, 7, and 2 farms respectively.

Swine farms were investigated for the number of animal heads, types of excreta collection, the amount of manure production, composting methods for both solid and liquid phases, bedding materials and their exchange frequencies, and the amount of compost production. Manure samples were collected separately in solid and liquid phases after solid and liquid separation. Compost samples, both solid and liquid were taken from compost applied arable land sites.

Analytical methods

Collected samples were stored at −4°C until analyzed. In order to measure total nitrogen (N) and total phosphorus (P) in samples, samples were pretreated in a block digester (BD40, LaChat, Milwaukee, WI, USA) with H2SO4 at 320°C, and subsequently passed through an auto water analyzer (QuikChem 8500, LaChat, USA) for analyzing the N and P contents. Total solids were calculated after drying the samples overnight in an oven at 105°C, and passed through a muffle furnace set at 550°C for 2 hours for the measurement of total volatile solids [8].

Calculation of nutrient loading amount

Nutrient loading may be defined as nutrient amounts applied to arable lands. In general, livestock manure is applied to arable land in the form of compost rather than its fresh form. During the composting period, organic compounds and nitrogen contained in livestock manure are oxidized and volatilized, which may be dependent on the methods of composting and storage duration. Thus, the fraction of nutrient loss in manure can be a reciprocal of nutrient loading coefficients (NLCs) which facilitate the calculation of nutrient changes from manure to compost as a dimensionless number.

Scenario construction and calculations for nutrient loading coefficients

For the calculation of nutrients from manure and compost in both solid and liquid phases, the measurement of nutrient concentrations in each sample is necessary and viable. However, the manure and compost amounts are difficult to measure, whereby the approximations by farmers’ statements or the excretion units from the regulatory body i.e. ME is required. Since, the statements from farmers might not be reliable to compare with the real values, the set-up of valid Cases is needed to ensure its objectivity. Hence, the NLCs for solid and liquid composts were calculated using Eq. 1 and Eq. 11.

Total nutrients produced in manure

For the amount of manure produced, the direct investigation of statements from farmers was set as Case I. The quantity of solid manure was calculated using Eq. 4, which was further multiplied by concentration of nutrients in manure (mg/kg) to get sum of nutrients in solid manure using Eq. 3. The volume of liquid compost was calculated using Eq. 15, which was then used in Eq. 13 to get sum of nutrients in liquid manure. Case 2 included reports from the ME [9], and was also calculated similarly by using both quantity and concentrations of manure from ME.

Total nutrients produced in compost

Eq. 6 measured the amount of solid compost production; the major concern would be weight reduction during the composting period of manure. Hence, three scenarios (S1–S3) were constructed: S1 was designated as the amount of the solid compost weight loss based on the farmer’s statements and was calculated using Eq. 8. S2 was adopted from a reference study by Zhu et al [10]. The volume reduction rate (%) during the composting period of reference study was converted to weight loss rate (%) by multiplying with bulk density and volume of mixture of manure and bulking agent (m3/yr) measured from compost samples using Eq. 9 [10]. On the other hand, the quantitative changes of P were theoretically substituted as zero, before and after composting. In practice, P loss occurs due to leachate and runoff [11]. Considering the nutrient loading to both the arable land and the entire environment, the constant P before and after composting was designated S3 (calculated using Eq. 10).

The amount of liquid compost produced was calculated using Eq. 14, the product of which was multiplied by nutrients in liquid compost to get the sum of nutrients in liquid compost (Eq. 12). The liquid compost amount is also inaccurate due to evaporation, although the concentration of nutrients can be measured from samples. Hence, the evaporation rate of liquid phase during the composting period was measured on site for 30 days (Eq. 16). Liquid composter with an effective volume of 200 m3 and surface area of 50 m2 was operated under three conditions of continuous, intermittent, and no-aeration, as previously mentioned. The height of the liquid composter was 4 m. The aeration rate in composter was maintained at 0.05 m3air/m3reactor·min, and intermittent aeration was performed with the aeration and pause duration of 40 and 20 min in every hour, respectively. The daily water reduction was multiplied by the area of reactor to get the daily evaporation (Eq. 17).

For solid compost

RESULTS AND DISCUSSION

The condition of investigated swine farms

Breeding scale of 15 farms producing solid compost were averaging 4,362±5,689 swines/farm and solid amounts after solid and liquid separation of swine manure were averaging 7,918.5±11,155.4 kg/d and each swine produced 1.65±0.57 kg/head·d solid manure (Table 1). Most of the farms were using saw dust (80%) and few used rice hull (20%) as bedding materials averaging 25.4±10.82 g/head·d by mixing with solid part of manure. All the farms used turning methods for air-supply and only 6 farms were using blower for aeration and turning methods together. The average amount of compost produced was 4,487.7±8,759 kg/d of which differences were occurred by breeding scale and the amount of bedding material used. The compost produced by each swine was 0.69± 0.5 kg/head·d.

A total of 14 farms investigated were producing liquid compost, with an average breeding scale of 3,198±2,849 swines/farm (Table 1). The influent for liquid composter is generally a part of water after solid and liquid separation. Thus, a certain amount of solid is present in the influent depending on the performance of a separator. The amount of liquid part has seasonal variation and direct investigation was impossible. Therefore, using the excretion unit values reported from ME, liquid part (urine+cleaning wastewater) was extracted of 4.23 kg/head·d. The average liquid amount after solid-liquid separation was 13,527±12,051 kg/d. There was no use of bedding material but three types of aeration methods were used for liquid composting i.e. continuous, intermittent, and no aeration. The average liquid compost produced was 12,329± 11,892 kg/d while each swine produced 3.70±0.30 kg/head·d liquid compost.

Nutrients in solid and liquid manure

According to the investigation, the solid part of about 1.65 kg/swine·d was produced for composting except bulking agent, which is 2 fold higher than ME report of 0.87 kg/swine·d. The deviation of mixture produced may be occurred by the excreta collecting structure such as scrapers, workforce collection, and slurry types. The concentrations of N and P in solid phase via this study and ME reports were 12.2 and 14.7 g N/kg and 4.7 and 10.2 g P/kg, respectively, as an average value from this study. Calculating the annual nutrient amounts based on both values, the amounts of N and P were 7.6 and 3.0 kg/head·yr, respectively, while ME reported values of 4.7 and 3.3 kg/head·yr, respectively, which are approximately 1.6 fold lower for N (Table 2). On the other hand, although the VS production of 136.6 kg/head·yr was assessed, the value cannot be compared with ME where the organic compounds have been presented in biochemical oxygen demand rather than VS.

The nutrient contents in the liquid component of the samples (Table 3) were measured and the average concentration of VS, N, and P were 14.3, 3.6, and 0.5 g/L, respectively, of which N values were relatively similar to the values of 3.5 g N/L and 0.78 g P/L from ME. The annual nutrient production for VS, N, and P were 22.1, 5.55, and 0.76 kg/head·yr respectively, while the ME reported 5.4 and 1.2 kg/head N and P, respectively.

Nutrients produced in solid and liquid compost

Analyses of the compost samples (Table 4) revealed the average concentrations of VS, N, and P were 411.9, 21.4, and 11.5 g/kg, respectively. The values for N and P were almost three and four times higher than the values before composting, probably due to the vaporization of water during the composting period [12,13]. Nutrients obtained for TA were 360.3, 16.4, 10.5 g/kg for VS, N, and P, respectively, while for values for T were 437.7, 23.8, 12.0 g/kg for VS, N, and P, respectively. Besides, the bulk density of T influenced by moisture content after composting was 35% lower than TA, which is contrary to our expectation; this could be a result of frequent turning. Use of bulking material was 9.9±3.1 kg/head·yr, which was similar to TA (9.6) and T (10.5).

Swine manure is first treated for solid and liquid separation, followed by the composting procedure performed independently. Before being applied to arable land as fertilizers, the solid part passes through the composting procedure with the addition of bulking agents such as sawdust, rice husk, or straw. For high quality compost, the addition of bulking agents is required for appropriate moisture, carbon to nitrogen ratio, and porosity. Thus, the VS content in a mixture of dewatered manure and bulking agents are increased when considering the dewatered manure itself. In general, most nutrients decrease due to microbial degradation, with the amount of nitrogen loss being the highest, mainly via ammonia volatilization [14–17].

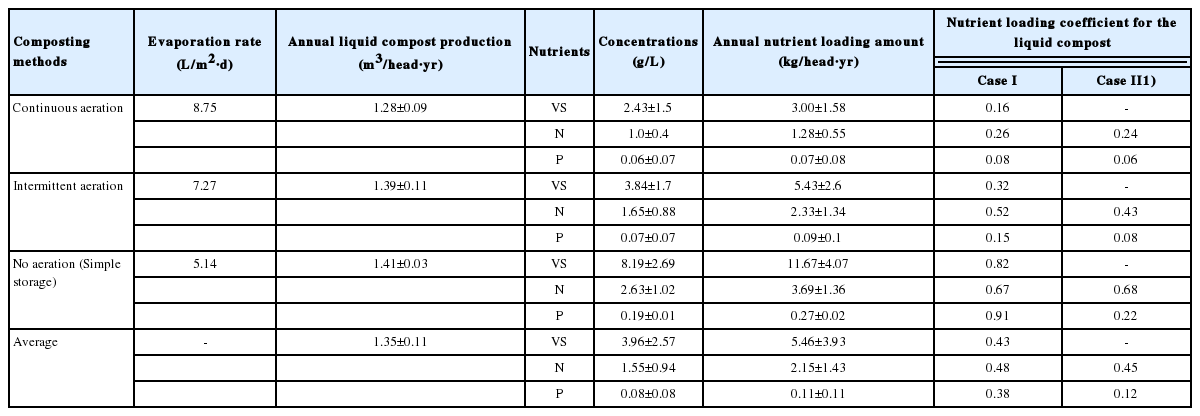

The characteristics of liquid compost differed considerably, according to the aeration methods used. As shown in Table 7, the average concentrations of VS, N, and P in liquid compost were 3.96, 1.55, and 0.08 g/L, respectively, which are about half the concentrations found in manure. The aeration intensity governed the concentrations of each nutrient. Under continuous aeration, the influent had the lowest concentrations of VS, N, and P, averaging at 2.4, 1.0, and 0.06 g/L, respectively. With no aeration and simple storage, highest concentrations of VS, N, and P were achieved, at 8.19, 2.63, and 0.19 g/L, respectively, which are 3.4, 2.6, and 3.2 folds higher than values from continuous aeration method. Consequently, continuous aeration led to the lowest annual amount of VS, N, and P produced at 3.0, 1.28, and 0.07 kg/head·yr, respectively, whereas no aeration resulted in higher amounts of 11.67, 3.69, and 0.27 kg/head·yr, respectively. On an average, 5.46, 2.15, and 0.11 kg/head·yr VS, N, and P were produced in the liquid compost, respectively. Reductions of nutrients in liquid compost when compared to influent were higher during continuous aeration than intermittent aeration. Simple storage (no-aeration) also had lowered nutrient concentrations compared to the influent, which might be due to precipitation and microbial degradation under anaerobic conditions. These results indicate that when manure is in liquid phase and is aerated or stored, there is a reduction in nutrients despite evaporation, as compared to the solid phase there is an increase in nutrients due to water evaporation.

Weight loss rate and evaporation rate of solid and liquid compost

Weight loss rates (%) for solid compost are presented in Table 5. For scenario S1, similar weight losses of 62% and 63% were observed for TA and T, respectively. Using the reference study, scenario S2 showed resultant weight losses of 71% and 80% by TA and T, respectively [10]. The high weight reduction in S2 might be due to the calculation with flat volume reduction from a reference. In S3, the theoretical phosphorus changes were believed to be zero (ΔP = 0) as P losses only occur via leachate or runoff. In this scenario, weight losses of 58% and 55% were calculated in TA and T, respectively.

Daily solid compost production (kg/head·d) presented in Table 5 was greatly affected by the weight loss rates (Eq. 6). The compost production for S1 was higher than Case I (0.78 TA; 0.64 T) compared to Case II (0.34 TA; 0.34 T). Compared to scenarios S1 and S2, scenario S3 had the lowest weight losses, which is why the compost production is also higher for both Case I (0.85 TA; 0.78 T) and Case II (0.37 TA; 0.40 T). The compost production for Case I was higher (0.78, 0.55, 0.85 kg/head·d) for TA compared to T only (0.64, 0.35, 0.78 kg/head·d) for all three scenarios, while in Case II the values for S1 were somewhat similar. However, in scenarios S2 and S3, T only (0.30, 0.40 kg/head·d) had higher compost production when compared to TA (0.26, 0.37 kg/head·d).

The final form of organic carbon is carbon dioxide and water under aerobic condition. However, the VS amount did not decrease much after composting since bulking agents were added to control proper moisture content of around 65%. Therefore, the actual nutrient loading on soil could be calculated by measuring the nutrient concentrations in compost and the amount of compost produced after considering the weight loss during the composting period. The weight of compost was lower when compared to the solid phase (i.e., fresh manure) probably due to moisture vaporization, leachate, and nutrient decomposition [18,19].

During composting of the liquid manure, depending on the intensity of aeration water evaporation occurs during storage and aeration. Hence, the evaporation rate of liquid compost for each aeration method was assessed on a farm having a 200 m3 liquid composter. The evaporation rates of 0.44, 0.36, and 0.26 m3/d were measured on a 50 m2 of surface area for continuous, intermittent, and no aeration, respectively, which corresponds to an evaporation rate of 8.75, 7.27, and 5.14 L/m2·d, respectively (Table 7). Continuous aeration resulted in higher evaporation rate, and even mere storage (no aeration) resulted in evaporated water content.

The average annual liquid compost production was 1.35 m3/head·yr, calculated by considering the evaporation rates of each composting method (Table 7). Of the three methods employed, continuous aeration produced bare minimum (1.28 m3/head·yr) and no aeration produced maximum (1.41 m3/head·yr) liquid compost. Due to the high evaporation rate, the final liquid compost obtained was lower at high intensity aeration and comparatively more under conditions of no aeration.

Nutrient loading coefficients

The solid phase NLCs obtained for combination of scenario 1 and case 1 (S1×Case I) were (VS, 0.67; N, 0.48; and P, 0.96) for TA while (VS, 0.93; N, 0.69; and P, 0.94) for T; these values were comparatively higher compared to the NLCs obtained with ME values (Table 6). When the nutrient amounts in compost were compared with the nutrients produced in fresh manure, the percentage of nutrient loss during the composting period were (VS, 33.0; N, 52.0; P, 4.0) for TA and (VS, 7.0; TN, 31.0; P, 6.0) for T.

Annual nutrient loading amount per head with combination constructed with nutrient loading coefficients for solid compost

The liquid phase NLCs are presented in Table 7. Based on the evaporation rate, the values obtained were (VS, 0.16; TN, 0.26; P, 0.08) for continuous aeration, (VS, 0.32; N, 0.52; P, 0.15) for intermittent aeration, and (VS, 0.82; N, 0.67; P, 0.91) for no aeration (simple storage). For liquid compost, the percentage (%) loss of nutrients was (VS, 84; N, 74; P, 92) for continuous aeration, (VS, 68; N, 48; P, 85) for intermittent aeration, and (VS, 18; N, 33; P, 9) for no aeration.

Using nutrient loading values, the NLCs from one swine (solid+liquid) obtained from sum of nutrients from solid and liquid phases were (VS, 0.79; N, 0.53; P, 0.71), whereas the annual VS, N, and P amounts were decreased by 21%, 47%, and 29%, respectively. Using values from ME, the obtained NLC values for N and P were 0.45 and 0.31, with nutrient losses of 55% and 69% N and P; this was 1.2 and 2.4 fold higher, respectively, than the farm investigated values.

Nutrient loadings from solid and liquid compost

Based on the above cases and scenarios, the annual amounts of nutrient loading on arable land were extracted according to composting methods TA and T (Table 6). Except N of S1×Case I, and both N and P of S3×Case I, all combinations with the TA composting method had increased nutrient loading amount compared to the values from T only. For Case II, all values for TA were lower than T for all scenarios. The difference is not much, except for the VS of S1×Case I. The average nutrient loading obtained from S1×Case I of solid compost for VS, N, and P were 112.1, 5.0, and 2.5 kg/head·d, respectively.

On an average, 5.46, 2.15, and 0.11 kg/head·yr VS, N, and P, respectively, were produced in the liquid compost (Table 7). The highest annual nutrient loadings were generated by no-aeration method, while continuous aeration produced the least amount of nutrients. Simple storage (no-aeration) also had lower nutrient concentrations compared to the influent, which might be due to microbial degradation under anaerobic conditions and precipitation.

The annual productions of VS, N, and P per head were obtained with the combination of S1×Case I, and the average values for solid and liquid compost, respectively. Thus, one swine breeding annually produces approximately 117.6, 7.2, and 2.7 kg/head·yr VS, N, and P in compost, respectively. The nutrient loading obtained for S1×Case II using ME values were 58, 4.6, and 1.4 kg/head·yr VS, N, and P, respectively, which was almost half of the values obtained using farm investigation.

The NLCs from Hanwoo reported by Won et al [20] were 0.96, 0.31, and 0.60, and the annual production derived were 213.4, 14.4, and 5.0 kg/head·yr, for VS, N and P, respectively. For dairy cattle, the calculated NLCs were 1.48, 0.60, and 0.66, with annual nutrient production of 423.4, 43.3, and 10.6 kg/head·yr, for VS, N, and P, respectively [21]. Per head nutrients (VS, N, P) produced from Hanwoo were 1.8, 2.0, and 1.9 fold higher, while they were 3.6, 6.0, and 3.9 fold higher for dairy cattle than the amounts generated from swine, respectively.

In 2012, the entire amount of livestock manure produced in Korea was 45,293 kt/yr, of which the highest fraction was occupied by swine manure (39.2%) followed by beef cattle (33.8%), chicken (14.5%), and dairy cattle (12.5%). Among the whole livestock manure, 88.7% of livestock manure was recycled as compost, and 9.1% of liquid phase mainly from swine manure was processed to release. Considering only the values of amounts of composting from NLCs of Hanwoo from Won et al [20], dairy cattle from Won et al [21], and swine from this study, and multiplying the nutrient (VS, N, P) concentrations obtained with the respective amount of manure produced, the respective amounts of VS, TN, and TP on soil after composting or storage period were found to be 606.8, 38.4, and 15.6 kt/yr for Hanwoo, 209.4, 17.7, and 4.5 for dairy cattle, and 517.5, 36.4, and 11.7 kt/yr for swine. Different from our expectation, the nutrients from Hanwoo manure on arable land contributed the most than from swine and dairy cattle manure.

Among OECD countries, Korea was ranked first in terms of N and second for P accumulation in soil. This is because of the direct calculation of the amount of nutrients generated by the number of livestock animals, as done in other OECD countries. The real manure management practices in Korea require treatment of manure before it is applied to arable land as fertilizer. As we know, during storage or treatment nutrients are lost from the manure, which are not calculated by OECD. Since circumstances for livestock breeding are very different in each country, it is very important to estimate the practical amount of nutrients on arable land in order to pursue sustainable agriculture. Other than swine manure, the investigation of all the livestock categories is required for building a database of nutrients in agricultural sector facilitates livestock manure management and conservation of environment.

In order to achieve sustainable agriculture, the recycling of nutrients from livestock manure is inevitable, and composting plays a key role. This study acknowledges that the Korean swine manure is primarily separated into solid and liquid phases before composting. Nutrients in compost applied to soil using ME values do not give a complete picture of the composting practices in Korea. It was observed that the composting was heavily affected by the weight loss rate during solid composting and evaporation rate during liquid composting. Farm investigation provided the combined nutrient load (solid+liquid) of VS, N, and P of 117.6, 7.2, and 2.7 kg/head·yr, respectively, from a single swine, while the ME values of nutrient loads were 58, 4.6, and 1.4 kg/head·yr for VS, N, and P, respectively. The nutrient load obtained with farm investigation was higher than that of obtained using ME values, suggesting that the nutrient calculations using ME values were half the values calculated in this study. This may be the cause of nutrient accumulation as different composting methods reduce nutrients differently. Providing the solid NLCs through building up a database of nutrient production from livestock manure accumulated for a few years, the NLCs will simplify the complex calculations to obtain the amount of nutrient loading directly from the nutrients from livestock manure on arable land, and its value will roughly represent the status of livestock manure and nutrient management.

ACKNOWLEDGMENTS

This research was supported by the Rural Development Administration of Korea (Project number, PJ011623) and partially by Kangwon National University. We also thank all the farm owners for providing samples.

Notes

CONFLICT OF INTEREST

We certify that there is no conflict of interest with any financial organization regarding the material discussed in the manuscript.