Effects of processing, particle size and moisturizing of sorghum-based feeds on pellet quality and broiler production

Article information

Abstract

Objective

This study aimed to assess the effect of pelleted and expanded sorghum-based feeds prepared with different moisture levels and particle size of ingredients on metabolizable energy, ileal digestibility of amino acids and broiler performance.

Methods

The experiment was performed with 720 male broiler chicks of the Cobb strain, with treatments of six replications, with 15 birds each; they were arranged in a completely randomized design and 2×2×2 factorial scheme (pelleted or expanded feed processing, 0.8% or 1.6% moisture addition in the mixer, and particle size of 650 or 850 microns).

Results

Higher pellet quality (pellets, % and pellet durability index [PDI]) was obtained in expanded diets and inclusion of 1.6% moisture. The particle size of 850 microns increased the PDI of final diet. All studied treatments had no significant effect on weight gain and broiler carcass and cut yields. Lower feed conversion occurred for birds fed pelleted feed at 42 d. The highest apparent metabolizable energy (AME) and apparent metabolizable energy corrected to zero nitrogen balance (AMEn) values of feed in the initial rearing phase (10 to 13 days) were observed in birds fed pelleted feed or for feed prepared with 1.6% moisture. The highest ileal digestibility coefficients of amino acids were obtained with the consumption of pelleted feed prepared with a particle size of 650 microns and 1.6% moisture.

Conclusion

Pelleted feed prepared with a milling particle size of 650 microns and 1.6% moisture provided increased ileal digestibility of amino acids and AMEn in the starter period. However, the expanded feed improved pellet quality and feed conversion of broilers at 42 days of age. We conclude that factors such as moisture, particle size and processing affect the pellet quality, and therefore should be considered when attempting to optimize broiler performance.

INTRODUCTION

Studies show that sorghum can be an alternative energy source because of its nutritional composition similar to corn, lower cost and increased grain availability in the domestic market. But, published data on the influence of conditioning temperature on the performance and nutrient utilisation of broilers fed maize- and sorghum-based diets are limited [1].

The physical form and thermal treatment of feeds can cause improvements in the use of nutrients due to superior digestibility and increased absorption [2]. In addition, broilers fed pelleted diets perform better compared to mash diets due to facility of eating g attributed ease of seizure of the ration, in addition to reducing food waste and energy expenditure during consumption [3]. However, the benefits of processed feeds on birds’ performance depend on pellet quality, i.e., a high proportion of intact pellets and low concentration of fine or disintegrated granules.

Size, shape and structure of particles influence digestibility and dispersion of nutrients, alter feed density, pellet quality, fluidity of ingredients within the mixing system, transportation and supply to feeders, and increase the energy consumed in milling [4]. Chewning et al [5] also described that smaller particles optimize the starch gelatinization process, favoring the digestibility of food. Another limiting factor in the quality of processed feeds is the amount of water added during preparation [6]. Both water added to the mixer and that added as steam during conditioning enhance particle adhesion, improving pellet quality, as documented by Buchanan and Moritz [7].

Therefore, the aim of this study was to assess the effect of pelleted and pelleted-expanded sorghum-based feeds prepared with different moisture addition levels (0.8% and 1.6% of water addition to the mixer) and two different particle sizes of ingredients (650 and 850 microns) on the performance, metabolizable energy of feed and ileal digestibility of amino acids of broilers.

MATERIALS AND METHODS

The experiment was conducted at the Federal Institute of Goiás State (Instituto Federal Goiano), Rio Verde, GO, Brazil. We used 720 day-old male broiler chicks of the Cobb strain, with initial average weight of 38±1.8 g. The experimental period was 42 days. The research project was approved by the ethics committee on animal research of the institution under protocol number 009/ 2014.

The experimental design was completely randomized in a 2× 2×2 factorial scheme (pelleted or expanded-pelleted feed processing; 0.8% or 1.6% moisture addition in the mixer; particle size of ingredients of 650 or 850 microns) with six replications of 15 birds in each cage.

Chicks were housed in batteries with four metal cages each (0.90×0.60×0.40 m). These cages were equipped with trough feeders and drinkers, a 100-W lamp for heating, and metal trays for excreta collection. The birds remained under constant lighting (natural and artificial) with temperature check twice a day and curtain handling. The average temperature registered during the experiment was 28°C±2.4°C, with a minimum of 19°C and a maximum of 39°C. Water and feed were provided ad libitum throughout the experimental period.

Experimental diets

The experimental diets were formulated based on sorghum and soybean meal to meet the nutritional demands for the initial (1 to 21 days), growth (22 to 35 days) and final (36 to 42 days) phases, according to the nutritional industry recommendations (Table 1).

Centesimal composition and calculated nutritional levels of the experimental feeds in the initial, growth and final phases

The experimental feeds were produced using an integrated broiler feed mill. The cereal milling method consisted of the use of co-milling using a hammer mill and the particle size was obtained by setting 5.0 mm for particles of 650 microns and 6.5 mm for 850 microns. Two different processes (pelleted and pelleted-expanded) were used to pelletize and expand the feeds, which consisted of the use of a Kahl expander and a Buhler pelletizer. The processing temperature was 82°C for 34 seconds in the conditioner for the pelletizer and 130°C for 11 seconds for the expander, producing pellet size of 4.00 mm. In the feeds of each rearing phase, the pellet percentage was measured by sieving the feed and separating the thin from the thick portion using a perforated container subjected to agitation [8]. In order to assess the durability index, 500 g of intact pellets was placed in a box rotating at 50 rpm for 10 minutes. After that, the sample was sifted through a sieve of 3.0 mm diameter and the pellets which remained in the sieve were considered whole [9,10].

Performance assessment

The animal performance variables assessed were body weight (BW), feed intake (FI) and feed conversion (FC) at 21 and 42 days of age. The number of dead birds was recorded at intervals as a criterion for correction of consumption and FC.

At 42 days of age, two birds with similar BW to that plot were slaughtered after 12 hour fasting to check the yield in percentage of carcass and cuts: breast, thigh, drumstick and abdominal fat. Carcass yield was calculated in relation to the live weight before slaughtering, and the cut yield depending on the hot carcass weight.

Nutritional utilization assessment

The total excreta collection method was used to determine the apparent metabolizable energy (AME) and the apparent metabolizable energy corrected to zero nitrogen balance (AMEn) of the experimental feeds from 10 to 13 and from 27 to 30 days of age. The AME and AMEn values were calculated using the equations described by Matterson et al [11].

GEing = Ingested gross energy (kcal);

GEexc = Extracted gross energy (kcal);

DM ing = Dry matter ingested (g)

NB = Nitrogen balance, ingested nitrogen – excreted nitrogen (g)

Samples of ileal digesta were collected at 21 d post hatching to determine the digestibility of amino acids as described by Sakomura and Rostagno [12]. Kaolin, a source of silica, was added to the feed of the initial rearing phase, at a level of 0.70%, in order to increase the levels of acid-insoluble ash, which was used as indigestible indicator [13]. At 21 days of age, five birds per repetition were slaughtered by cervical dislocation. The ileum was exposed by abdominal incision, a segment of 30 cm ending at 4.0 cm from the ileocecal junction was removed, and its content collected.

Samples of the experimental feed, ileal digesta and excreta were sent to the Animal Nutrition Laboratory of the IFGoiano, Rio Verde, Goiás, Brazil, to determine the content of dry matter (INCT-CA G-003/1 method) and crude protein (INCT-CA N-001/1 method), according to the standard techniques of the Brazilian National Institute of Science and Technology in Animal Science (INCT-CA; [14]). The GE values were determined using an IKA C5001 adiabatic calorimeter. To avoid amino acid losses, the digesta were dried in a lyophilizer at −53°C during 72 hours. The total amino acids of feeds and digesta were determined using high-performance liquid chromatography. The acid-insoluble ash was determined according to the method described by Santos et al [15]. From the laboratory results, the coefficients of ileal digestibility of amino acids were determined, as described by Sakomura and Rostagno [12].

Data analysis

The data underwent analysis of variance using the SISVAR 5.0 software [16] and the means were compared by the Tukey test at 1% and 5% probability.

RESULTS

The expanded feeds of the initial, growing and final phases had higher pellet percentage by an average 11.6% compared with pelleted feeds. The inclusion of 1.6% moisture in the experimental feeds raised the pellet percentage by 9%. The expansion of the feeds of the different periods increased the pellet durability index (PDI) by 13.47% in relation to the pelleted feeds, while the addition of 1.6% water in the growth and final periods increased the PDI by 8.37%. An effect of granulometry of the ingredients on PDI was observed only for the final phase feed. The particle size of 850 microns increased the PDI of this feed (Table 2).

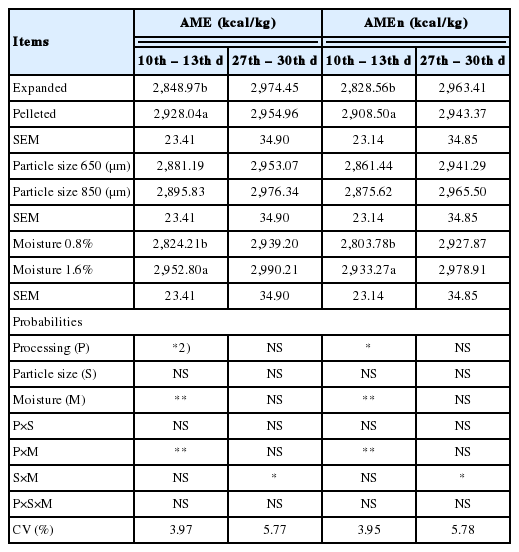

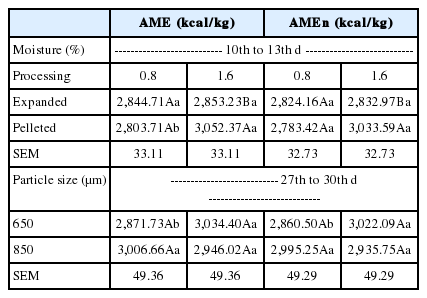

Table 3 shows the values of AME and AMEn. The results demonstrate the lack of effect of the processing methods, particle size and moisture levels during chicken growth phase (27 to 30 days). However, throughout the initial rearing phase (10 to 13 days), the birds fed pelleted feeds, as well as those with 1.6% moisture addition, presented higher values of both AME and AMEn.

The moisture levels had significant interaction with processing methods in the initial rearing phase (10 to 13 days) and with particle size during the growth phase (27 to 30 days). The statistical breakdown of interactions, shown in Table 4, reveals that AME and AMEn values did not differ between the moisture levels (0.8% and 1.6%) in the initial rearing phase for broilers given expanded feeds. However, birds fed pelleted feeds at 1.6% moisture presented AME and AMEn values higher than those given the expanded feeds. During the growth phase, feeds produced with a particle size of 650 microns and 1.6% moisture resulted in improved energy use (AME and AMEn).

Breakdown of the processing×moisture and particle size×moisture interactions regarding AME and AMEn of the feeds, determined, respectively, in the birds’ initial rearing phase (10 to 13 days old) and growth phase (27 to 30 days old)

There were no differences in the feeds prepared with a particle size of 850 microns considering the different moisture levels.

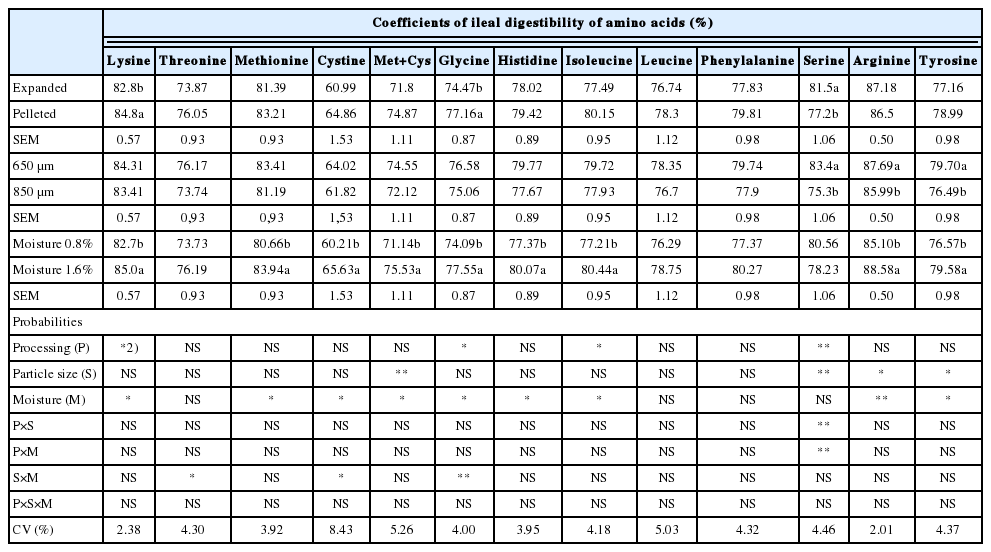

Assessing the main effects, we observed higher values of ileal digestibility coefficients in sorghum-based pelleted feeds when compared to the expanded feeds for the amino acids lysine and glycine (Table 5). The birds fed processed feeds with 650 micron particle size showed higher CID for serine, arginine, lysine and tyrosine. When assessing the effects of moisture addition to the mixer, we observed that the amino acids lysine methionine, cystine, met+cys, glycine, histidine, isoleucine, arginine, and tyrosine showed higher CID with 1.6% moisture addition (Table 5).

We observed interaction between milling particle size and moisture for the amino acids threonine, cystine and glycine. The statistical breakdown of the interaction of particle size and moisture level (Table 6) showed that the highest CID values were obtained with consumption of feed prepared with particle size of 650 microns and 1.6% moisture level. Conversely, there was no effect on that variable of moisture for the feeds prepared with particle size of 850 microns.

Breakdown of moisture×particle size interaction of ileal digestibility coefficients of amino acids threonine, cystine and glycine

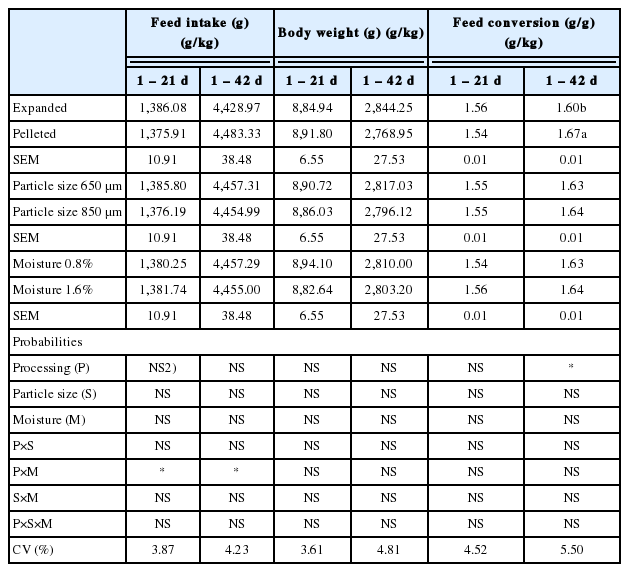

There were no significant effects on FI and weigh gain of the birds at 21 and 42 days of age. At 42 days of age, we observed higher FC for birds fed pelleted feeds compared to those that consumed expanded feeds (Table 7).

There was a significant interaction between processing and moisture for FI at 21 and 42 days of age (Table 7). When breaking down the interaction, we found that the birds fed expanded feed with 1.6% moisture had higher FI compared to that with 0.8% moisture addition at 21 days. However, no difference was observed for the FI of animals fed pelleted feeds prepared with different moisture additions. In contrast, at 42 days of age, we observed that the birds fed pelleted feed with 0.8% moisture had higher FI while FI of the birds fed expanded feed did not change as a function of moisture addition (0.8% and 1.6%).

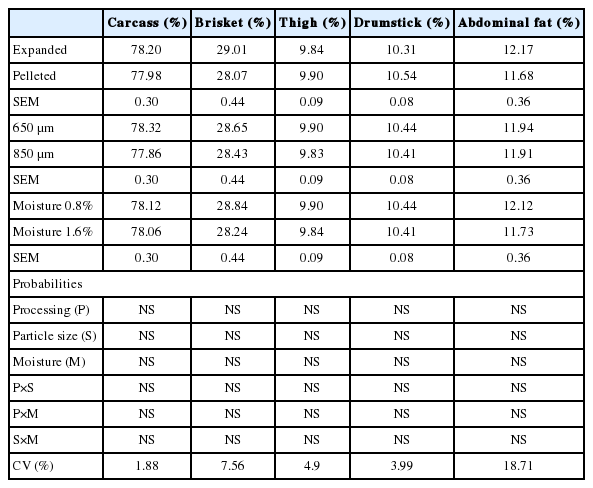

There were no effects of the processing methods, particle size and moisture level on carcass, drumstick and abdominal fat yields (Table 8).

DISCUSSION

Higher pellet quality (pellets, % and PDI) was obtained in expanded feeds and inclusion of 1.6% moisture. These results are in accordance with a study of U.S. feed mills, which indicated that feed processed in an expander before pelleting as compared to conventional conditioning-pelleting improved pellet quality [17]. Muramatsu et al [4] reported that conditioner-expander-pelleting treatment and moisture addition up to 21 g/kg of feed are effective strategies to enhance pellet quality. Water addition enhanced pellet quality due to its capillary property, which helps to keep particles together [18]. Also, retention of moisture has been linked to an increase in starch gelatinization and improvement in pellet quality [7].

Although coarser particles have resulted in higher PDI in the final feeds, it is important to emphasize that use of coarse granulometry in this study agrees with the recommendations in the literature. The use of particles larger than 1,000 or 1,500 microns can cause fracture of pellets [19]. For this reason, it is recommended that in corn or sorghum-soybean meal feeds for broilers, particle size should be approximately 600 to 900 microns to achieve the highest PDI [19,20].

Unlike for the pellet quality, in the initial rearing phase (10 to 13 days of age) the birds fed pelleted feeds provided AME and AMEn on average 2.8% higher than obtained for the expanded feeds. The addition of 1.6% moisture in the mixer provided AME and AMEn values on average 4.6% higher compared to the use of 0.8% moisture. According to Buchanan and Moritz [7], the addition of higher levels of water during preparation results in improvements in pellet quality and therefore a greater feed particle hydration. The higher the water absorption index is, the higher the degree of starch gelatinization promoted by thermal processing [21] and the better the results of nutrient utilization expressed by AME and AMEn values.

The reason for higher AME and AMEn values in pelleted feeds prepared with 1.6% moisture in relation to expanded feeds might derive from the fact that intense food processing increases the Maillard products, reducing protein and starch solubility and digestibility, as described by Zimonja et al [22], Taylor and Dewar [23] and Selle et al [24]. Furthermore, sorghum starch granules are surrounded by a matrix protein layer which can limit enzyme access, decreasing digestibility [25], hindering energy utilization even more of feeds subjected to treatments with high temperatures. Therefore, in this study the temperature of 130°C during 11 seconds to which the expanded feeds were submitted may have been a limiting factor of maximum energy utilization.

The same behavior was observed when assessing the digestibility coefficients of amino acids (DCAA), where the highest efficiency was reached with the use of pelleted feeds prepared with smaller particles (650 microns) and higher moisture amounts (1.6%).

The advantages observed in thermal processing on the amino acid digestibility can be attributed to protein denaturation, with alterations to three-dimensional structures. The relatively subtle impact of steam-pelletizing on protein digestibility agrees with the position taken by Svihus and Zimonja [26] in their review. Increased enzyme efficiency in protein digestibility and hence of amino acids was also obtained by Surek et al [27] using smaller particle sizes of ingredients.

However, the effects of adding moisture during the thermal processing of the pellets on nutrient digestibility are not clear. According to Buchanan and Moritz [7], increased moisture can interact with other components of the feed, aiding thermomechanical reactions in the pellets. As the temperature increases, the water molecules reach a higher energy state, contributing to destabilize proteins and improve their digestibility. However, severe heating can cause destruction of the primary structure of the proteins and thus break or form some covalent bonds and decrease protein digestibility [26]. The use of high temperature for the expansion of the pellets in this study may have negatively influenced the digestibility of amino acids. Similar to these results, [28] observed that moderate temperatures and short treatment times showed no effects on amino acid availability, but intensive heat treatment significantly reduced amino acid availability. Boroojeni et al [29] also observed negative effect on ileal digestibility of amino acids in broilers by raising the long-term conditioning temperature (pelleted feeds at 85°C for 3 min).

There was no effect of feed processing on the birds weigh gain. However, unlike the results observed in this study, Lundblad et al [30] found higher weigh gains in broilers fed expanded feeds when compared to pellets. Although with lower values of AME and DCAA in the starter phase, we observed improved FC at 42 days in birds fed expanded feeds in relation to pelleted feeds.

Abdollahi et al [31] and Abdollahi et al [32] showed that although increasing conditioning temperatures above 60°C or 90°C negatively affected the nutrient utilization, the better pellet quality obtained in feeds processed at these temperatures restored the performance of broilers. According to the authors, the magnitude of the body weigh gain and FI responses of broilers fed pellet feeds reflect a balance between the negative effect of conditioning at higher temperatures on nutrient availability and the positive effect on pellet quality. In general, the effect of thermal treatment on better feed efficiency is partly due to the fact the higher proportion of whole pellets facilitates broiler FI and decreases feed waste, thereby reducing feed energy used for maintenance [33].

The particle size did not affect broiler performance in any of the assessed age ranges. Similar results were described by Zang et al [34], who found no difference in FI, WG, and FC when studying pelleted feeds with particle sizes of 953 and 597 microns. Similarly, Boroojeni et al [29], when comparing feeds prepared by different processes, conditioning temperatures and organic acids addition (pelletized at 70°C, pelletized at 85°C for 3 min, and expanded at 110°C or 130°C from 3 to 5 seconds) did not observe changes in broiler performance.

Pelleted diets prepared with a milling particle size of 650 microns and 1.6% moisture provided increased ileal digestibility of amino acids and AMEn in the tarter period. However, the expanded feeds improved pellet quality and feed conversion of broilers at 42 days of age. We conclude that factors such as moisture, particle size and processing affect the pellet quality, and therefore should be considered when attempting to optimize broiler performance.

ACKNOWLEDGMENTS

We are grateful to the company Brasil Foods for supporting this research and to the National Council for Scientific and Technological Development (CNPq) for the financial support (process number 487959/2013-2).

Notes

CONFLICT OF INTEREST

We certify that there is no conflict of interest with any financial organization regarding the material discussed in the manuscript.