Effects of Replacing Pork Back Fat with Canola and Flaxseed Oils on Physicochemical Properties of Emulsion Sausages from Spent Layer Meat

Article information

Abstract

The objective of this study was to investigate the effects of canola and flaxseed oils on the physicochemical properties and sensory quality of emulsion-type sausage made from spent layer meat. Three types of sausage were manufactured with different fat sources: 20% pork back fat (CON), 20% canola oil (CA) and 20% flaxseed oil (FL). The pH value of the CA was significantly higher than the others (p<0.05). The highest water holding capacity was also presented for CA; in other words, CA demonstrated a significantly lower water loss value among the treatments (p<0.05). CA had the highest lightness value (p<0.05). However, FL showed the highest yellowness value (p<0.05) because of its own high-density yellow color. The texture profile of the treatments manufactured with vegetable oils showed higher values than for the CON (p<0.05); furthermore, CA had the highest texture profile values (p<0.05) among the treatments. The replacement of pork back fat with canola and flaxseed oils in sausages significantly increased the omega-3 fatty acid content (p<0.05) over 15 to 86 times, respectively. All emulsion sausages containing vegetable oil exhibited significantly lower values for saturated fatty acid content and the omega-6 to omega-3 ratios compared to CON (p<0.05). The results show that using canola or flaxseed oils as a pork fat replacer has a high potential to produce healthier products, and notably, the use of canola oil produced characteristics of great emulsion stability and sensory quality.

INTRODUCTION

Nowadays, consumers are gradually interested in foods that not just support nutritional needs, also concern health benefits (Kim et al., 2010). People are concerning about their bad or irregular dietary habits, especially depend too much on meat consumption. According to Mathijs (2015), the consumption of meat appears two different aspects: positive and negative effects for human health in developing and developed countries, respectively. Indeed, high quality products are regarded as healthy products that contain low amounts of fat, additive agents, salt content (Kruk et al., 2014). Omar et al. (2009) noted that people demand foods containing a variety of nutrients for a lifetime of health.

Accordingly, modern society requires food companies to produce healthier products. For developing healthier products, the most important thing is to manufacture foods that reduce the unhealthy aspects and improve the healthy aspects which mainly depend on the type of raw materials and the fat sources.

The consumption of spent layer as partial meat resources has increased (Kim, 2014). At the same time, many researchers are putting efforts to optimize the use of spent layer because of their depreciation. According to Wu and Wang (2012), the disposal of spent layer can lead to making some economic and environmental concerns in the poultry industry. However, these resources, despite being less tender than broiler meat, can be a good raw material (Hollender et al., 1987). Moreover, by using spent layer at the end of a laying cycle as a raw material for meat products with other ingredients of higher nutritional value, it is possible to provide economic benefits to the poultry industry (Souza et al., 2011).

Generally, emulsion-type meat products are manufactured from beef, pork, or chicken with pork back fat (Jo et al., 2015), and these conventional meat products contains up to 30% fat (Choi et al., 2010b). According to Youssef and Barbut (2009), the fats and oils play important roles, especially regarding the functional and sensory quality, for many food products. However, many researchers have reported that high fat intake can cause cardiovascular disease and obesity because of the production of low density lipoprotein-cholesterol (Jo et al., 2015). The reduction of animal fat through the use of non-meat materials, for example dietary fiber and isolated soy protein, could produce healthier meat products (Choi et al., 2010b). Vegetable oils have also been used as replacements of animal fat in low-fat meat products (Ambrosiadis et al., 1996; Muguerza et al., 2001).

Canola and flaxseed oils contain a high amount of omega-3 fatty acids (Bozan and Temelli, 2008; Moon et al., 2011; Suksombat et al., 2013). González-Esquerra and Leeson (2001) noted that omega-3 fatty acids have the possibility for reducing rates of various diseases, such as cardiovascular disease and diabetes. In addition, according to the WHO (2003), to reduce coronary heart disease, linoleic acid is the best replacement of saturated fatty acids. These bioactive compounds can also give some assistance to body growth (Omar et al., 2009). In medical and scientific communities, mono-unsaturated fats acquired from dietary sources have received attention for their potential health benefits (Rhee et al., 1988). However, because of their high polyunsaturated fatty acids (PUFA) values, vegetable oils have the possibility to quickly reduce the product stabilities (Choo et al., 2007). Xiong and Jiang (2015) noted that providing oxidative stability with the use of vegetable oils with high PUFA values would be an important challenge to researchers.

The objective of this study was to investigate the effects of canola and flaxseed oils as a pork fat replacer in emulsion sausages made from spent layer meats to find ways to optimize the health ratings of spent layer products. Furthermore, these products could be a valuable food resource for people who do not consume pork materials for various reasons (i.e., religion, preference, etc.).

MATERIALS AND METHODS

Materials

Twenty spent layers (Hy-line; 70 weeks old) were purchased from JUNG-WOO-FOOD Agricultural Co., Ltd. (Korea) and approximately 20 kg of pork back fats were purchased from a local meat shop. These materials were then transferred to polyethylene-vacuum-pack bags and vacuum-packaged using a vacuum sealer (SBV-400TS, SB Tech, Gimpo, Korea). They were stored at −24°C until needed for product manufacture. Fresh canola oil was purchased from a local market and flaxseed oil was purchased from SSAM-G-FNB Organic Product Co., Ltd. (Seoul, Korea).

Meat batters and emulsion sausages preparation

All subcutaneous fat and visible connective tissue were removed from the chicken breast. Approximately 20 kg of the spent layer breast meat and pork back fat were separately ground using a meat chopper (M-12S, HANKOOK FUJEE MACHINERY Co., Ltd., Hwaseong, Korea) with a 6-mm plate. Three meat batters were prepared for each treatment with the formulations given in Table 1. The first emulsion sausage was a control (CON) prepared with 20% pork back fat and the other two emulsion sausages were prepared with each 20% canola and flaxseed oils as the fat replacer. At three-step emulsification process was performed to produce high-quality emulsion sausages. In the first step, the chicken breast was emulsified for 6 min in a silent cutter (OMF-500, Ohmichi Co., Ltd., Maebashi, Japan) together with ice (0°C), 1.5% salt, 0.3% curing salt (93.1% salt, 5.9% sodium nitrite, and 1.0% sodium carbonate), and 0.3% sodium tri-polyphosphate. Second, 0.5% bologna seasoning, 0.5% beef powder, 0.5% sugar, 0.1% black pepper, 0.5% chopped onion, and iced water (2°C) were added and emulsified for 4 min. Then, 4% potato starch, 1% isolated soy protein, 0.05% smoke solution and ice water (2°C) were finally added and mixed for 4 min. For the meat batter experiment, the meat batter samples were stored at 4°C in the dark and under vacuum conditions up until the analyses for color, pH, emulsion stability, and water holding capacity (WHC). Another set of meat batter samples was filled into collagen casings (#260, Nippi Collagen Ind., Tokyo, Japan; 26-mm diameter) using a sausage filler (DK-9, Friedr. Dick GmbH & Co. KG, Deizisau, Germany). They were then heated to 80°C for 30 min in a water bath (BW-20G, Jeio Tech Co., Daejon, Korea). The emulsion sausage products were cooled with cold running water for 30 min and dried at 4°C for 1 h. After drying, the products were stored at 4°C in the dark and under vacuum conditions until quality analyses.

Instrumental surface color and pH evaluation

The instrumental surface color of each meat batter was determined by using chroma-meter (CR-400, Konica Minolta Sensing Inc., Osaka, Japan) measuring lightness (Commission Internationale de l’Eclairage [CIE] L*-value), redness (CIE a*-value) and yellowness (CIE b*-value); illuminate C was calibrated with a white standard plate (Y = 93.6, X = 0.3134, y = 0.3194). Chroma (C*) was measured using data processing equipment (DP-400, Konica Minolta Sensing Inc., Japan). The color measurement was performed 5 times on each batter sample. To measure the pH, a homogenizer (PH-91, SMT Co., Chiba, Japan) was used to homogenize 5 g of each batter in 50 mL of distilled water for 1 min at 10,000 rpm. The pH values were recorded in triplicate using a pH meter (SevenEasy pH, Mettler-Toledo GmbH, Schwerzenbach, Switzerland).

Emulsion stability and water holding capacity

The emulsion stability and WHC were measured in triplicate using the Choi et al. (2007) method and Laakkonen et al. (1970) method with slight modifications. First, a sieve (4×4 cm, 19 mesh) was put in the middle of a specially formed centrifuge tube. Approximately 10 g of meat batter samples were then placed on the sieve, and covered with aluminum foil. Samples were cooked at 75°C for 30 min in a water bath and cooled in a 2°C±1°C chilling room for 30 min. Each water and fat layer was measured using tube gradation and then calculated as follows:

Samples were then centrifuged at 1,000 rpm for 10 min at 4°C. Aluminum foil and meat samples were then discarded, and each tube was determined by weight change after 24 h at 100°C. The WHC was measured by calculating the percentage of the total moisture and the water loss as follows:

Warner-Bratzler shear force and texture profile analysis

The Warner-Bratzler shear force (WBSF) and the texture profile analysis (TPA) were performed at room temperature using a texture analyzer (TA-XT2i, Stable Micro Systems Ltd., Goldalming, Surrey, England). Ten cubed (1×1×1 cm; width×length×height) samples taken from the central portion of each emulsion sausage were equilibrated to room temperature. The shear force (WBSF) values were determined using a 3 mm Warner-Bratzler shear blade. The texture analysis (TPA) conditions were as follows: pre-test speed, 2.0 mm/s; post-test speed, 5.0 mm/s; maximum load, 2 kg; head speed, 2.0 mm/s; distance, 8.0 mm; and force, 5 g. Values for the shear force (kg), hardness (kg), springiness (cm), cohesiveness, gumminess (kg), chewiness (kg), and resilience (mm) were determined.

Sensory evaluation

Spent layer sausages were cooked to 80°C for 30 min in a water bath (BW-20G, Jeio Tech Co., Korea) and then cooled to 4°C. The sensory evaluation was performed in triplicate on each sample coded with a randomly selected digit number. The 10 semi-panelists were asked to evaluate the color, texture, taste, aroma, and overall acceptance on a 9-point hedonic scale: 1-most unpleasant, very unpleasant, moderately unpleasant, slightly unpleasant, neither pleasant nor unpleasant, slightly pleasant, moderately pleasant, 9-most pleasant. The panelists were required to cleanse their palates with water between samples.

Fatty acid composition

The fatty acid composition was determined in triplicate using a gas chromatograph (YL6500, YL Instrument, Anyang, Korea). The lipid fraction of the sausages was extracted according to Folch et al. (1957) and methylated as described by AOAC (1995). Fatty acid methyl esters were separated using an Omega wax-320 fused silica capillary column (30 m×0.32 mm i.d., 0.25 μm film thickness; Supelco, Inc., Bellefonte, PA, USA). The fatty acid peaks were identified by comparing with the retention times and peak areas of fatty acids standard mixtures (Supelco 47015-U, USA).

Statistical analysis

The complete data set was subjected to one-way analysis of variance using R-version 3.1.2 with the “Agricolae” library (The R-foundation for Statistical Computing, Vienna, Austria). The statistical significance of the differences between means from different treatments was determined by Duncan’s multiple range test (p<0.05).

RESULTS AND DISCUSSION

pH and color evaluation

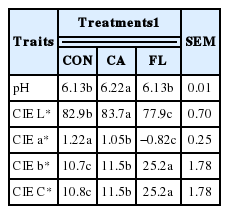

The results of the pH values and colors of the meat batters are presented in Table 2. The pH of the canola oil sausage (CA) was higher than for the other treatments (p<0.05). Similar results, presenting higher pH values in meat batters formulated with vegetable oils than in batters with pork back fat were reported by Choi et al. (2009) and Choi et al. (2010a). However, there were no significant differences between control and flaxseed oil sausage (FL).

The lightness (CIE L*) of the CA was significantly higher than that of other treatments, and the CON had the highest redness (CIE a*) value (p<0.05). This result agrees with Koo et al. (2009) who indicated that the lightness of emulsions before cooking was higher in vegetable oil treatments than those in tallow. Similar results were also reported by Youssef and Barbut (2009) in which the lightness of meat emulsions prepared with canola oil were higher than those prepared with the beef fat treatments, and the results for redness exhibited a reversed pattern. They also indicated a relationship and difference between smaller oil globules and larger fat globules with reflection as an explanation for these results. However, FL, even though it was manufactured with vegetable oil, showed the lowest lightness value (p<0.05). This was probably a result of its own high-density yellow color, which could also be confirmed from the highest chroma (CIE C*) value of FL. This result agrees with Park et al. (2005), who obtained the lowest lightness from low-fat hamburger patties produced with olive oil. FL also had the highest yellowness (CIE b*) value compared to other treatments (p<0.05). Many researchers have reported that the yellowness values increased when the meat batters were manufactured with vegetable oils as animal fat replacement (Park et al., 2005; Koo et al., 2009). For this reason, FL was likely to be affected by consumer preferences.

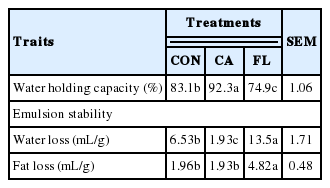

Water holding capacity and emulsion stability

The WHC and emulsion stability of the meat batters were affected by the emulsified formulation, which designed using different fat sources (Table 3). The addition of canola oil as a pork back fat replacer in emulsion sausages significantly increased the WHC more than the traditional sausage results (p<0.05). In addition, the CA showed the lowest water loss among the treatments (p<0.05). Xiong and Jiang (2015) noted that the interfacial protein membrane and the size of the emulsion droplet played important roles in forming the stability of the emulsions. Canola oil could form emulsions more tightly than beef fat because of its smaller fat globules, which provided extensive surface space to protein (Youssef and Barbut, 2009). They reported that meat batters manufactured with canola oil, at the protein levels below 13%, had significantly lower water losses than meat batters manufactured with beef fat. Many researchers have also found that meat emulsions prepared with vegetable oils, especially with canola oil, had equivalent or higher WHC than those of emulsions prepared with animal fat (Álvarez et al., 2011; Youssef and Barbut, 2011). Moreover, according to (Park et al., 2005; Koo et al., 2009), patties prepared with vegetable oils had decreased cooking loss. Although the batter temperature increased to 20°C, the emulsion stability of the meat products designed with vegetable oil was stable (Ambrosiadis et al., 1996). However, there were no significant difference in fat losses between CON and CA. On the other hand, water loss and fat loss were significantly higher in FL (p<0.05). In other words, FL had the most unstable emulsion stability among the samples. This is probably related to different inner structures such as the size of fat globules or different susceptibility to processing temperatures.

Shear force and texture profile analysis

The effects of canola and flaxseed oils on the textural properties of the emulsion sausage are also given in Table 4. The shear force of CA was significantly higher than that of CON and FL (p<0.05). Except for springiness, the highest hardness, cohesiveness, gumminess, chewiness, and resilience values were observed in the CA treatment (p<0.05). Youssef and Barbut (2011) noticed that adding canola oil as a beef fat replacement significantly increased the hardness, cohesiveness, chewiness, and gumminess. According to Choi et al. (2009), the meat emulsions prepared with various vegetable oils and rice bran fiber as the pork back fat replacer had higher hardness values than those of meat batters containing pork back fat. However, in this experiment, the texture profile of FL showed similar results to that of CON, which added pork back fat. These results were probably due to the lower WHC and emulsion stability of the FL treatment, especially compared to those of CA. These results showed that the use of canola oil could result in a stable emulsion and better texture because of its high WHC.

Sensory evaluation

Table 5 shows the sensory evaluation results. The color score of CA was higher than for other treatments (p<0.05). This probably resulted from its higher lightness value (Table 2), which created a synergic effect between the chicken breast (i.e., the white muscle) and the clean liquid canola oil. The texture of CA was also higher than for CON and FL because of its higher textural properties (Table 4). However, there was no significant difference in taste among the samples. The lowest flavor and overall acceptance values were found in emulsion sausages prepared with flaxseed oil. These might be due to the specific strong flavor and yellow color of flaxseed oil which could be divided into likes or dislikes according to individual preference.

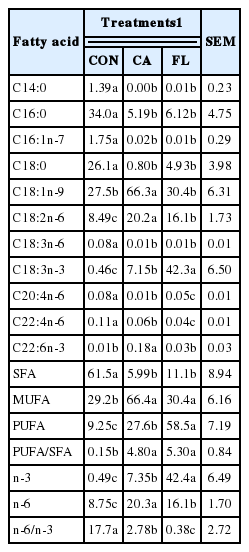

Fatty acid profile

Table 6 shows the fatty acid profile of emulsion sausages made from spent layer with fat replacements. The highest saturated fatty acids (SFA) were observed in CON (p<0.05), which was manufactured with pork back fat. This content mainly consists of palmitic acid (C16:0) and stearic acid (C18:0). The PUFA content of FL was significantly higher than for the other treatments (p<0.05), and most of the PUFA were made up of alpha-linolenic acid (C18:3n-3). According to Bozan and Temelli (2008), flaxseed oil retained over 80% unsaturated fatty acids, which mostly consist of linolenic acid. CA also contained higher PUFA than the conventional one (p<0.05). In this case, however, PUFA were mostly made up with linoleic acid (C18:2n-6). The highest oleic acid (18n:1n-9) was observed in CA (p<0.05), which was prepared with canola oil. Many researchers also found that canola oil has over 50% oleic acid (Moon et al., 2011; Jung, et al., 2013). Emulsion sausages manufactured with canola and flaxseed oils had PUFA/SFA ratio over 4. These values were 4 to 5 times higher than for CON. A similar trend was observed by Souza et al. (2011), who manufactured mortadella sausages with spent layer meat and soybean oil and 4 to 5 times higher PUFA/SFA ratio than traditional sausages manufactured with beef and pork fat. The ratios of the omega-6 to omega-3 fatty acids were significantly (p<0.05) higher in CON than those of in CA and FL approximately 6 to 45 times, respectively. The ideal ratio of omega-6 to omega-3 was approximately 1, and this lower ratio has potential to prevent various diseases (Simopoulos, 2006). Current people gradually consume omega-6 fatty acids, approximately 12 to 30 times higher than omega-3 fatty acids, in their diets (Choo et al., 2007; Park et al., 2014). As a result, CA and FL have the possibility to enhance omega-3 fatty acid contents for health benefits.

CONCLUSION

Using canola oil as animal fat replacer in manufacturing emulsion sausages not only shows a high potential for emulsion stability derived from its own remarkable WHC, but also appears a stable and tight texture have led to appear highest texture score in sensory evaluations. Moreover, the use of canola oil also showed a high sensory evaluation scores for color, taste, flavor, and overall acceptance, which equivalent to conventional one. Furthermore, the addition of canola oil could help to form ideal ratios of PUFA to SFA and omega-6 to omega-3 fatty acids.

ACKNOWLEDGMENTS

This research was supported by Export Promotion Technology Development Program, Ministry of Agriculture, Food and Rural affairs, Republic of Korea.

Notes

CONFLICT OF INTEREST

We certify that there is no conflict of interest with any financial organization regarding the material discussed in the manuscript.