Effects of Bedding Material Composition in Deep Litter Systems on Bedding Characteristics and Growth Performance of Limousin Calves

Article information

Abstract

The objective of this study was to evaluate the effects of different litter mixture compositions on bedding system temperature, pH and volatile fatty acid and ammonia-N (NH3-N) content, and the serum physico-chemical parameters and growth indices of calves. Thirty-two Limousin calves (280±20 kg) were randomly assigned to four groups (n = 8 for each group) according to the bedding system used: i) control with soil only (CTR); ii) mixture with 50% paddy hulls (PH), 30% saw dusts (SD), 10% peat moss (PM) and 10% corn cobs (CC) (TRT1); iii) mixture with 15% PH, 15% SD, 10% PM, 40% CC, and 20% corn stover (CS) (TRT2); iv) mixture with 30% PH, 10% PM, 40% CC, and 20% CS (TRT3). The litter material combinations of different treatments were based on the cost of bedding system materials in China. The cost of four treatments from low to high: Control<TRT1<TRT2<TRT3. The control was no-cost treatment. The diet consisted of 60.8% silage and 39.2% concentrate (dry matter [DM] basis). The NH3-N level (271.83 to 894.72 mg/kg) was lowest for TRT1 (p<0.0001) and highest for TRT2 (p<0.0001). The acetate, propionate and butyrate levels were highest for the control group (p<0.0001). In all the groups, the pH value (6.90 to 9.09) increased at the beginning and later remained stable at below 9.09. The temperature of deep litter increased at the first week and reached the maximum (42.1°C) on day 38. 3,5,3′-Triiodothyronine (T3) levels in the TRT1 group animals (p<0.0001) were lower than those in the control and TRT2 animals. 3,5,3′,5′-Tetraiodothyronine (T4) in the TRT1 group (p = 0.006) was lower than that in the other treatment groups. Cortisol (COR) in the control and TRT1 group was lower (p<0.0001) than that in the TRT2 and TRT3 groups. Corticosterone (CORt) in the control group was higher (p<0.0001) than that in the treatment groups. The findings indicate that the deep litter bedding systems provided better conditions for animal health and growth performance compared with the control system. Furthermore, the litter composition of TRT1 was found to be optimal among the three treatment groups.

INTRODUCTION

The bedding system is widely used in beef cattle farms in Europe and Japan, but less use in China. Different bedding system materials and their mixtures have different characteristics (Kapuinen, 2001). Typically, bedding systems are made of paddy hulls and saw dusts. When the environmental temperature drops, animals need more energy to maintain their body temperature (Young, 1975; Christopherson, 1983; Fox et al., 1988; Eckert et al., 2000) and their food consumption needs to increase (Olbrich et al., 1973; McDowell et al., 1976; Fox et al., 1988); these excessive energy requirements may even cause body weight loss (Webster, 1971; Christopherson, 1985). Therefore, there is a need for bedding systems that help animals maintain their body temperature and body weight during cold weather. Currently, the bedding systems in China is soil only, few farms use paddy hulls and saw dusts for bedding systems. China burns a lot of crop and forestry by-products such as paddy hulls, saw dusts, corn stover, and corn cobs as a waste. Therefore, the scientific community and animal welfare groups have been actively searching for a better bedding system from the viewpoint of animal welfare and growth performance.

The quality of a bedding system depends on the components, moisture content and aeration. A well-fermented bedding system makes a comfortable and warm setup for animals during winter. Paddy hulls, saw dusts, peat moss, corn cobs and corn stover are common residual products that are available cheaply in China. Paddy hulls, saw dusts and peat moss are the commonest material for bedding systems. Corn cobs and corn stover are less used for bedding systems. Because these materials are soft and porous, a combination of straw, peat and wood chips as bedding system material is thought to provide optimal height for the bedding system; moreover, such a bedding system would still have sufficient capacity to keep the animals from sinking into the bedding (Kapuinen, 2001). Corn cobs are porous and contains 45% cellulose, 35% hemicellulose and 15% lignin (Howard et al., 2003) and is a useful material in China for bedding systems. Corn stover are a more easily usable energy source for microorganisms compared to saw dusts and peat moss (Kirchmann, 1997). The total moisture content of a bedding system, including raw material and manure, should be 50% to 60% (Campbell and Darbyshire, 1990; Rynk et al., 1992; Tiquia et al., 1998). Paddy hulls, saw dusts, corn cobs and corn stover are common residual products and their moisture is lower. The proportion of peat moss should be controlled within an appropriate range or the moisture content of the bedding system will exceed 60% at the end of the fermentation (Kapuinen, 2001). The composting temperature cannot be lowered by a decrease in oxygen but by aeration (Kapuinen, 2001). Therefore, an optimal bedding system should be porous and fluffy.

The objective of this study was to evaluate the effects of different proportions of litter components on the temperature, pH, and volatile fatty acid (VFA) and ammonia-N (NH3-N) content of the bedding system, as well as the calves’ average daily gain (ADG) and serum physico-chemical parameters. Through this study, we aimed to explore feasible and suitable bedding systems for use in Chinese cattle farms.

MATERIALS AND METHODS

Experimental animals and the bedding systems

Thirty-two Limousin calves (average age, 8 months; mean weight, 280±20 kg) were randomly assigned to four groups (n = 8 in each group). The treatments were: i) control bedding system with soil only (CTR); ii) bedding system with a deep litter mixture comprising 50% paddy hulls (PH), 30% saw dusts (SD), 10% peat moss (PM), and 10% corn cobs (CC) (TRT1); iii) bedding system with a mixture comprising 15% PH, 15% SD, 10% PM, 40% CC, and 20% corn stover (CS) (TRT2); iv) bedding system with a mixture comprising 30% PH, 10% PM, 40% CC, and 20% CS (TRT3). Corn cobs and corn stover were ground using an ensilage cutter into 2 to 3 mm long pieces. Physical data of the materials used for the deep litter were analyzed (AOAC, 1990) before they were used in the bedding systems (Table 1).

The Limousin calves were housed in four separate uninsulated barns for each treatment. Each barn was 4 m×10 m in dimension and included a pit of size 2 m×10 m that was at a depth of 0.7 m into the floor (this depth was enough for a fermentation period of 7 weeks). The distance between the bottom and the top of the deep litter in each pit was 0.8 m. Bulls were not kept in the barns until the temperature of the litter reached 15°C about 25 cm from the top of the deep litter in the pit, which required 7 days. The litter was ploughed about 30 cm in depth at noon every two days, in order to ensure that the oxygen content of the litter decreased more slowly. The calves were given a total mixed ration (TMR) diet, which consisted of 60.8% silage and 39.2% concentrate (Table 2). Calves were feed twice daily, at 0600 and 1800 h; they had ad libitum access to TMR and fresh water throughout the experimental period. The experimental period was 56 days, which included 7 days of composting and 49 days of sampling. Samples of diets were collected once weekly for dry matter (DM) determination, and then composited by period. Samples of litter materials were collected before the trial for DM, carbon (C), nitrogen (N) and C/N determination. The samples were dried in an oven at 65°C for 48 h, and mill-ground to pass through a 1-mm screen (FZ102, Shanghai Hongji instrument Co., Ltd., Shanghai, China) for chemical analysis. The experimental protocol was approved by the Animal Care and Use Committee of China Agricultural University.

Analysis of the bedding systems

The C, N, and C/N of the litter material were determined using a rapid multi-element analyzer (Vario MAX; Elementar Analysensysteme GmbH, Hanau, Germany). Dry matter content of the litter material, silage and concentrate mix was determined by oven-drying the samples at 65°C for 24 h using the methods described by Van Soest et al. (1991). The N content in the feed was determined using the rapid-N multi-element analyzer (Rapid-N III; Elementar Analysensysteme GmbH, Germany).

The temperature of the bedding systems was measured using a digital thermometer (TP101 pen recording thermometer, Shanghai Automation Instrument Factory, Shanghai, China) daily at 0800 h at a depth of 0.25 m from the top of the deep litter; readings were taken from five different parts and the average was calculated. The environmental temperature inside the barns was also measured.

For measurement of pH, samples of deep litter from five different parts were collected daily at 0800 h at a depth of 0.15 m from the top. On each occasion, the samples were stored at about 4°C in a container covered with a lid in order to preserve them and immediately transported to the laboratory for further analysis. For the analysis, 10 g of the sample was weighed and mixed with 50 mL distilled water and placed in a 4°C refrigerator for 60 min. Then, the pH of the supernatant was measured using a digital pH meter (Sartorius Basic pH Meter PB-20, Sartorius AG, Goettingen, Germany).

For measurement of the VFA and NH3-N content, samples were collected from five different parts of the deep litter at the depth of 0.15 m from the top, at 0800 h at the end of the 4th week of sampling. Then, 5 g of the sample was mixed with 25 mL distilled water and placed in a 4°C refrigerator for 60 min. The solution was then filtered through a rapid filter paper and centrifuged at 3,000 rpm for 10 min. Next, 1 mL of the supernatant was mixed with 0.2 mL of 250 g/L (w/v) metaphosphoric acid and left to stand in Eppendorf tubes for 30 min. The VFA contents were determined use a gas chromatograph equipped (Agilent 6890N GC, Agilent Technologies, Santa Clara, CA, USA) with a capillary column (30.0 m×320 μm×0.5 μm, Catalog No:19091J-213, HP-INNOwax, Santa Clara, CA, USA) by the method of Erwin et al. (1961). For determining the NH3-N content, 5 mL of the supernatant was mixed with 1 mL of 20 g/L (w/v) H2SO4, and NH3-N was measured using an ultraviolet spectral photometer (UV-VIS 8500, Shanghai Techcomp, Shanghai, China) by the method of Broderick and Kang (1980).

Analysis of the physico-chemical parameters and growth indices of the calves

At the end of the sampling period, 20-mL blood samples were collected by venipuncture before feeding in the morning and stored in vacuum blood collection tubes. The blood samples were kept in an ice box until they were centrifuged at 3,000 rpm for 10 min at 4°C. Serum samples were protected from light and separated in Eppendorf tubes and stored at −4°C for determining the levels of thyrotropin-releasing hormone (TRH), 3,5,3′-triiodothyronine (T3), 3,5,3′,5′-tetraiodothyronine (T4), cortisol (COR), and corticosterone (CORt) using a radioimmunoassay counter (Sn-69513, Shanghai Rihuan Photoelectric Instrument Co., Ltd, Shanghai, China).

The calves were weighed at the beginning and at the end of the trial to determine ADG. Individual dry matter intake (DMI) data was collected three times a week, together with animal weight was to adjust the feed to gain rates (F/G) for calves of each treatments.

Statistical analysis

The data from the experiments were analyzed using the general linear model (SAS, 2004), and the means were compared for significance by the least square means procedure. The data of VFA, NH3-N, serum physico-chemical parameters and growth indices were subjected to analysis of variance using the following model:

where: yij, the experimental data; μ, the general mean; α, the treatment effect (I − Control, TRT1, TRT2, TRT2); and ɛ, the error term.

Effects of the factors were declared significant at p<0.05 by Duncan’s multiple range tests.

RESULTS

Physical data of the litter material

The DM, NDF, C, N, and C/N values are shown in Table 3. The DM content of all the raw materials was higher than 88%. Peat moss also had the lowest C content and C/N ratio. The N content of all the raw materials was less than 1.1%. The C/N ratio was maximum in saw dusts, at 344.4%; it was below 60% in the remaining materials.

Temperature

The difference in temperature between the environment and the treatments are shown in Figure 1. Environmental temperatures gradually reduced during the trials and lowest at −13°C. The temperatures of the bedding systems were higher than those of the environment. All the treatments show the same trend with regard to the temperature difference with the environment. The temperatures of all the bedding system treatments were higher than those of the control during the trail. The difference between the environment and the bedding systems was lower in the early part of the experiment, but it gradually increased and stabilized later. The maximum difference in temperature between the environment and the bedding systems was observed for TRT3; it was 42.1°C on day 38. The temperatures of all the bedding system treatments tended to be similar towards the latter period of the experiment, between 24°C and 30°C.

The difference in temperature between the environment and the treatments are shown in Figure 1. The temperature of the bedding systems was measured using a digital thermometer daily at 0800 h at a depth of 0.25 m from the top of the deep litter; readings were taken from five different parts and the average was calculated. The environmental temperature inside the barns was also measured.

pH

The pH value of treatments are shown in Figure 2. The range of pH values of the treatments was 6.90 to 7.38 at the beginning of the trial. It gradually increased till it was around 8.50 for most of the experimental period. The maximum pH value observed was about 9.04. The values for TRT1 were lower than those for the other treatments at some time points.

For measurement of pH, samples of deep litter from five different parts were collected daily at 0800 h at a depth of 0.15 m from the top. On each occasion, the samples were stored at about 4°C in a container covered with a lid in order to preserve them and immediately transported to the laboratory for further analysis. For the analysis, 10 g of the sample was weighed and mixed with 50 mL distilled water and placed in a 4°C refrigerator for 60 min. Then, the pH of the supernatant was measured using a digital pH meter.

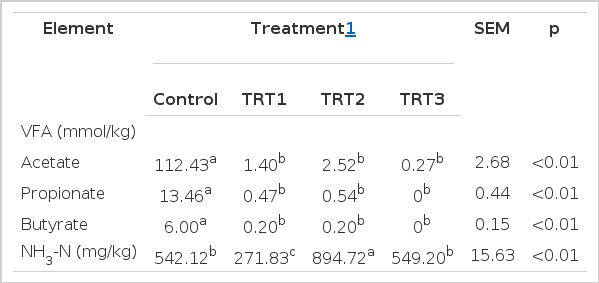

Volatile fatty acid and ammonia-N content

Acetate, propionate and butyrate levels in the control were significantly higher than those in the treatment groups (p<0.01; Table 4). Propionate and butyrate was not detected in the TRT3 system. The NH3-N content was significantly higher (p<0.01) for TRT2 and lower (p<0.01) for TRT1.

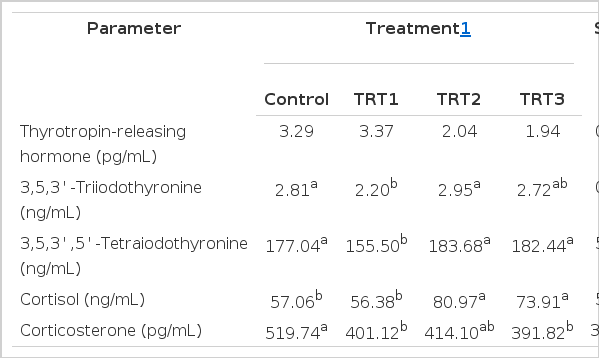

Serum physico-chemical parameters

Effects of the bedding systems on the serum physico-chemical parameters are shown in Table 5. The bedding system had no significant effects on TRH. The T3 level in the TRT1 group was significantly lower (p<0.01) than that in the control and TRT2 groups. The T4 level in the TRT1 group was significantly lower (p<0.01) than that in the other treatment groups. The COR values for TRT2 and TRT3 were significantly higher (p<0.01) than those for the control and TRT1 groups. The CORt values for the control were significantly higher (p<0.01) than those for the TRT1 and TRT2 groups.

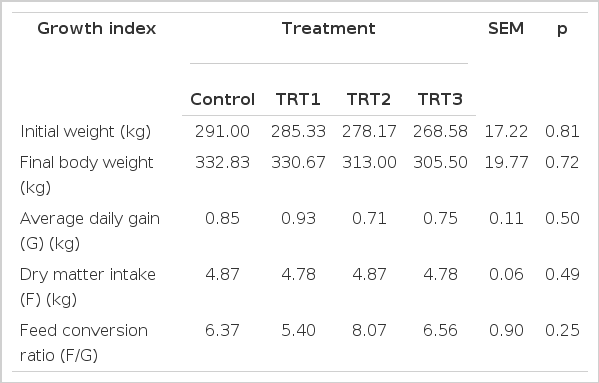

Growth indices

The effects of the bedding system on growth performance are shown in Table 6. Although the ADG for the TRT1 group was higher than that for the other groups, the difference was not significant. The value of DMI was not significantly different between the groups. The F/G value for the TRT1 was lower than that for the control group, but there was no significant difference between the treatment groups (TRT1, TRT2, and TRT3).

DISCUSSION

In this study, we have investigated the characteristics of bedding systems comprising different compositions of litter material, as well as their effects on the health of animals. In general, we found that the bedding systems formed by fermentation of deep litter performed better than the control system that contained soil only. The different characteristics and their effects are explained in the paragraphs below.

The raw materials used in our trials had high DM content (above 88%); therefore, the moisture content was low. Lower moisture content prevents the growth of mold; therefore the materials had the appropriate moisture content. It has been reported that C/N ratio of 25 to 35 is appropriate for composting (Waksman and Hutchings, 1936; Waksman and Cordon, 1939; Hoyle and Mattingly, 1954; Gray et al., 1971b; Hong et al., 1983; Rynk et al., 1992). The nitrogen loss in a compost with a C/N ratio of 25 to 35 is 30% (Eklind et al., 2000). Low nitrogen concentration could have a negative influence on composting temperature. Thus, animal waste leads to a nitrogen source which is required for maintenance of optimal composting temperature in bedding systems.

In our experiment, the fermentation caused the bedding materials to reach a pleasant temperature so that the animals were comfortable. Kapuinen (2001) reports that the moisture content and carbon supply in deep litter are the most important factors that affect the composting temperature. The C/N ratio of the materials used in this study was in the range of 24.39 to 34.44, which has been reported to correspond to the optimal composting temperature (Hong et al., 1983). Therefore, compared with the control system, all the treatments with bedding systems provided external heat that assisted the animals’ resistance to low temperature. The composition ratio of a deep litter system may have different effects on fermentation and therefore, the temperature of the bedding system. Kapuinen (2001) supposed that the lack of oxygen and low degradation in deep litter would lead to a low composting temperature. Moreover, Suler and Finestein (1977) found that composting occurred at a faster rate at an oxygen concentration of 18% compared to 10%. In our experiment, TRT1 and TRT3 had a higher temperature than TRT2 from day 8 to 39 of composting; this was probably attributable to the high proportion of paddy hulls in the former treatments. It is possible that the porous texture of paddy hulls improves the breathability and therefore oxygen concentration of the bedding system, which is beneficial to fermentation.

The pH values determined in the present study were attributable to the ammonia produced by the fermentation of animal waste. Dewes (1996) reported that high fermentation temperature increases the potential for loss of ammonia. High ammonia in a bedding system causes a high pH value. That TRT1 had some time points with a lower pH than other treatments may have been due to the materials in this bedding system were fermenting at a higher temperature. The pH values are believed to reflect the ammonia content of deep litter, and animal feces and urine are the main sources of ammonia in bedding systems. Therefore, the high pH values observed in the present bedding systems maybe because the materials used have good permeability for ammonia.

In our study, the VFA content was lower in the treatment groups compared to the control; it is possible that the soft and porous structure of the bedding system led to easy loss of VFAs. Acetate formed the largest portion of VFAs in present study. It has been reported that acetic acid may cause erosion of the teeth in people who handle silicone sealers in the car industry without taking preventive measures (Ernstgard et al., 2005). High concentrations of acetic acid may have a similar effect on the health of calves. Thus, low acetate in bedding systems was good for animal welfare. Low NH3-N in the environment is associated with good animal health (Hickey et al., 2002). From our results, it seems that the composition of TRT1 was ideal for the utilization of NH3-N by microorganisms, as the NH3-N content was lowest for this group. According to Misselbrook and Powell (2005), in contrast with concrete surfaces, bedding systems allow the retention of urine on their absorbent surface layer and reduce ammonia emission. The NH3-N level was significantly higher in the TRT2 group; this was probably caused by the high DMI and low ADG in the animals, which caused excess animal waste. Similarly, the low DMI and high ADG in the TRT1 group may have caused the lesser animal waste and lower NH3-N.

Thyrotropin-releasing hormone is a hypothalamic tripeptide that plays a role in stress response in animals (Arunabha Ray, 2006). TRT1 showed a significant lower for 3,5,3′-Triiodothyronine (T3), 3,5,3′,5′-Tetraiodothyronine (T4), COR, and corticosterone. Previous experiments have shown that T3 could provide feedback at the level of the hypothalamus to down regulate TRH synthesis (Segerson et al., 1987). Moreover, concentrations of T4 in the serum of cattle were decreased to below detectable levels by daily T3 injections (Thrift et al., 1999; Radcliff et al., 2001). High levels of ammonia could affect the respiratory system (Hickey et al., 2002) and thereby increase the stress level. The lower levels of T3 and T4 in TRT1 may be due to the lower concentration of NH3-N in this group. It is proved that lower NH3-N decreased the stress. Cortisol and corticosterone levels were significantly lower in TRT1. Cortisol, also known as hydrocortisone, is a steroid hormone (more specifically a glucocorticoid) produced by the zona fasciculata of the adrenal cortex (Scott, 2008). Lower COR and corticosterone may be attributable to the warm environment; that is, lower temperatures may induce stress in animals. Cortisol and corticosterone plays an important role in glycogenolysis, the breaking down of glycogen to glucose-1-phosphate and glucose, in liver and muscle tissue (Palme, 2000). It has been shown that animal raised on bedding systems could resistance to cold weather and reduce the stress.

Most researchers report that floor type has no effect on DMI (Levy et al., 1970; Andersen et al., 1991). It is reported that bulls housed from 4 to 5 months of age (507 kg live weight) in slatted and straw-bedded pens have similar food intake (Levy et al., 1970). Although there was no significant difference in the intake of DM between groups in this trial, TRT1 and TRT3 showed lower DMI. Fallon and Harte (1985) found lower carcass gains in cattle housed on slatted floors compared to those housed on solid floors bedded with saw dusts. This was similar to our study, where TRT1 showed higher ADG compared with control though the difference in ADG was not significant; this was probably because of the high proportion of saw dusts, suitable temperature, low VFA and low NH3-N with this system. TRT1 showed a higher feed conversion ratio although there was no significant difference in this trial. The TRT1 system is, therefore, associated with good economic benefits in this trial.

CONCLUSION

The deep litter systems had higher temperature and lower VFAs compared with the control system. Moreover, the animals housed on the deep litter bedding systems had lower levels of stress-related hormones. The mixture used in Treatment 1 (50% paddy hulls, 30% saw dusts, 10% peat moss and 10% corn cob) may be optimal for bedding systems, based on the results of this study.

ACKNOWLEDGMENTS

This study was financially supported by the Earmarked Fund for Modern Agro-Industry Technology Research System (Beef Cattle and Yaks, CARS-38), the National Scientific Supporting Fund (2008BADA7B04), and Beijing Supporting Central College Fund (201202910411136).