Carcass Characteristics and Meat Quality of Korean Native Ducks and Commercial Meat-type Ducks Raised under Same Feeding and Rearing Conditions

Article information

Abstract

This study was conducted to compare carcass characteristics and physico-chemical meat quality in two different genotype ducks raised under identical feeding and rearing conditions. A total of ninety 1-d-old Korean native ducks (KND, n = 45) and commercial meat-type ducks (Grimaud, n = 45) were fed same experimental diets during 56 d and 42 d, respectively to obtain similar slaughter weights. The experimental diet for starter period contained 20% crude protein (CP) and 2,900 kcal nitrogen corrected true metabolizable energy (TMEn)/kg of diet and that for grower period contained 17% CP and 3,050 TMEn/kg of diet. Average daily gain and feed efficiency of KND were inferior to those of commercial meat-type ducks (p<0.05). Carcass weight was not different between two genetically different ducks, but carcass yield of KND was significantly higher (p<0.05) than that of commercial meat-type ducks. There were no significant differences in cooking loss and pH of breast meat between two genetically different ducks, but water holding capacity of KND was significantly higher than that of commercial meat-type ducks. The linoleic acid and total polyunsaturated fatty acid of breast meat from KND were significantly higher (p<0.05) than the corresponding part from commercial meat-type ducks. Significant differences were detected in water holding capacity and the content of linoleic acid and polyunsaturated fatty acid, which were significantly higher in KND, whereas growth performance tended to be superior in commercial ducks. At the market weight, the meat from KND was judged to have better qualities with regard to higher water holding capacity and greater content of polyunsaturated fatty acid compare with meat from commercial meat-type duck.

INTRODUCTION

In the last 10 years, the consumption of duck meat has increased rapidly, and it is expected that it will continue to grow in the future (FAO, 2012). The duck industry in Korea has been also continuously increased within a short period and this increment results not only from expanding commercial meat-type breeds, but also from a growing population of local breeds (FAO, 2012). Korean native ducks (KND, Anasplatyrhynchos) have colored-feathers and unique meat flavor and texture (Kim et al., 2012). But they are relatively slow-growing with a poor feed conversion rate (Hong et al., 2012) and are reared for a longer period (8 wk) as compared to commercial meat-type breeds (Kim et al., 2012).

Modern commercial ducks grow faster due to genetic selection, efficient rearing system and improved nutrition supply (Adeola, 2003). But, selection for fast growth and high yield may adversely impact the functional and sensory qualities of meats (Dransfield and Sosnicki, 1999). In most Asian countries, there is increasing preference for indigenous breeds called quality poultry meat over the fast-growing breeds developed from commercial breeding companies. In a previous study, Muhlisin et al. (2013) reported that the breast meat of KND had higher sensory attributes with better fatty acid profiles as compared with commercial meat-type ducks.

Several factors have been shown to influence poultry meat quality such as genetic strains, age, sex, nutrition, environment, slaughtering and processing conditions (Poole et al., 1999). In this study, the environmental and slaughtering conditions were set similarly to minimize the effects influencing meat qualities. Both duck breeds were also provided with the same starter and grower diets. The objective of the present study was to compare the carcass yield and physico-chemical quality of meats from KND and commercial imported breeds raised under the identical feeding and rearing conditions.

MATERIALS AND METHODS

Animals, management and sample preparations

The male Korean native ducklings (KND, n = 45) and commercial meat-type ducklings (Grimaud, n = 45) were received on the day of hatch from a local hatchery (breeder flocks at 45 and 40 wk of age each), individually weighed and randomly assigned into three replicate pens, respectively. Fifteen ducks were housed on rice husks in floor pens of same size (2.0×1.5 m) and provided 23/1 light/dark cycle throughout the experimental period. The pens contained rice husks to a depth of 10 cm. The ducklings were initially reared at 33°C; the room temperature was gradually decreased by 4°C weekly until a final temperature of 22°C was reached. The room temperature was automatically controlled using whole brooding heaters. They were fed same experimental diets during 56 d and 42 d, respectively to obtain similar slaughter weights. The starter diet, from 1 d to 3 wk, contained 20% crude protein (CP) and 2,900 kcal nitrogen corrected true metabolizable energy (TMEn)/kg of diet and the grower diet from 3 wk until the end of the experimental period, contained 17% CP and 3,050 TMEn/kg of diet, as shown in Table 1. The experimental diets were formulated to meet and exceed the nutrients requirements of NRC (1994) and Korean feeding standard for poultry (2012), and processed as crumble form for starter period or pellet form for grower period, respectively. The diets and water were provided for ad libitum intake. Each pen was provided with a single feed trough and 4 nipples with a nipple watering line. Body weight and feed intake on a pen basis were recorded weekly and feed efficiency was also calculated.

At the end of the experimental period, 9 ducks whose body weight were similar to the group mean (3 pens with 3 birds sampled per pen) were selected and weighed individually. They were carefully transferred to plastic crates and brought to the slaughter house. The ducks from different genotypes were slaughtered under similar conditions to minimize any other factors influencing the meat qualities. Feed was withdrawn 12 h before slaughter. They were sacrificed by neck cut, scalded with hot water (60°C for 3 min), and feathers removed mechanically. Carcasses were eviscerated manually and portioned into commercial cuts such as neck, breast, leg and wing. The breasts were immediately chilled for 30 min in ice water and transferred to icebox and then prepared separately for further analyses. All animal care procedures were approved by Institutional Animal Care and Use Committee in Konkuk University.

Meat quality analyses

To determine the cooking loss, the breast from each duck was cut into pieces about 3 cm thick, boiled individually in polyethylene bags immersed in 80°C water bath for 30 min and cooled at room temperature for 30 min. The cooking loss was calculated from the weights of uncooked and cooked meats. The water holding capacity (WHC) was estimated according to filter paper pressed method (Grau and Hamm, 1953). A 300 mg of breast meat was weighed on a Whatman filter paper (No. 2, Buckinghamshire, UK). The samples were pressed between two plexiglass plates for 3 min. The areas of pressed sample and water were measured using planimeter (Type KP-21, Mitutoyo, Kawasaki-shi, Japan). The pH values of breast meats were measured 6 h post slaughter using a pH meter (Model 340, Mettler-Toledo, Greifensee, Switzerland). Briefly, 1 g of breast meat was cut into small pieces and homogenized with 9 mL of distilled water for 1 min in an Ultra-Turrax (Model No. T25, Janke and Kunkel, Staufen, Germany). Each sample was measured in triplicate and the mean values were used. The instrumental color of fresh meat, including lightness (L*), redness (a*) and yellowness (b*), was measured by a reflectance colorimeter (CR 210, Minolta, Tokyo, Japan) using illuminant source C. Color was measured in triplicate on the bone-side surface of each sample. The colorimeter was calibrated throughout the study using a standard white ceramic tile.

Chemical analyses

The total lipids of breast meat in both groups were extracted as described by Folch et al. (1957) and methylated as described by An et al. (1997). The fatty acid composition was measured by gas-liquid chromatography (Agilent 6890 N, Agilent Technology, Santa Clara, CA, USA) using 0.32 mm i.d. ×30 m capillary column (HP- Innowax, Agilent Technology, USA). One micro liter of sample was injected (split 1:10, 260°C) and then carried out at a flow rate of 1.0 mL/min using helium. The initial column temperature was set at 150°C for 1 min and increased to 200°C at 15°C/min and to 250°C at 3°C/min. The flame ionization detector was set at 280°C. The peaks were identified by comparison with standard mixture of fatty acid methyl ester.

Amino acid contents in freeze-dried breast meats were determined by amino acid analyzer (Sykam S433, Sykam GmbH, Eresing, Germany), following hydrolysis in 6 N HCl for 22 h at 100°C (Spackman et al., 1958). Methionine and cysteine were determined on samples that had been oxidized in performic acid prior to acid hydrolysis according to the method of Moore (1963).

Statistical analysis

All data were statistically analyzed using analysis of variance, and significant differences of obtained means were determined at the level of p<0.05 (SAS Institute, 2004). One pen was considered as the experimental unit for each performance parameter. The experimental unit was put on each duck for the other measurements.

RESULTS AND DISCUSSION

Growth performance and carcass characteristics

Growth performance and carcass characteristics of KND and commercial meat-type ducks raised under the identical diet and feeding condition are presented in Table 2 and 3. The initial body weight of commercial meat-type ducks was significantly higher (p<0.01) than that of KND, although there was no difference in pre-slaughter body weight at the end of experiment. The daily weight gain and feed efficiency of commercial meat-type ducks were significantly higher (p<0.01) than those of KND. There was no significant difference in carcass weight, but carcass yield of KND was higher as compared with commercial meat-type ducks. The breast weight of KND was significantly higher than that from commercial meat-type ducks (p<0.05). The weights of leg and abdominal fat of KND were comparable with those of commercial meat-type ducks.

In this study, KND took longer than commercial meat-type ducks to achieve a similar body weight at slaughtering. The genotypes displayed differences in growth performance, as expected, commercial meat-type breed grew faster than KND. The commercial meat-type ducks are one of the fastest growing and capable of a feed efficiency of 45 g of body weight gain per 100 g feed consumption with above 3,000 g body weight at 42-d old (Adeola, 2003). On the other hands, KND showed relatively low daily weight gain and poor feed conversion ratio despite of some genetic improvements. The growth of KND in present study agreed with other findings that male KND had a 176 g of daily feed intake with 2,820 g body weight at 56-d old (Hong et al., 2012). In our previous study, KND showed slow-growth characteristics, especially for late growth stage, with poor feed efficiency (Choo et al., 2014). The carcass yields of KND and commercial meat-type ducks were 70.0% and 67.5%, respectively, which agreed with our previous study that it tended to be higher in KND at similar slaughter weights (Muhlisin et al., 2013).

Meat quality

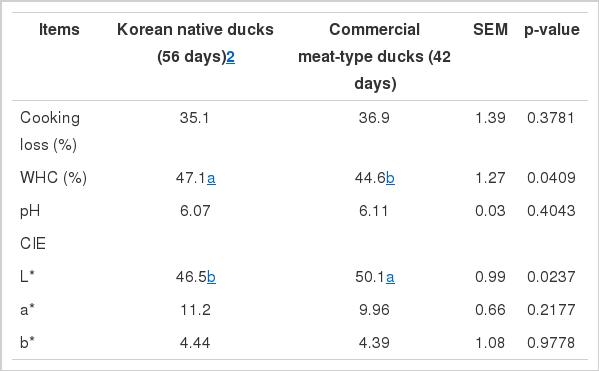

The cooking loss, WHC, pH, and color of breast meat from KND and commercial meat-type ducks are presented in Table 4. The WHC of breast meat from KND was significantly higher (p<0.05) than that from commercial meat-type ducks with similar body weight. No significant differences were observed in cooking loss and pH between both genotypes. The breast meat from KND showed significantly lower (p<0.05) lightness (Commission Internationale de l’Eclairage [CIE] L*) than that of commercial meat-type ducks, although there were no differences in redness (CIE a*) and yelllowness (CIE b*).

There is increasing preference for indigenous breeds, called quality meat, over the fast-growth breeds developed from commercial breeding companies. It is necessary to establish more precise meat quality standards for indigenous breeds, including KND, to ensure their expanding consumption. The cooking loss of breast meat from commercial meat-type ducks, Cherry Valley, ranged from 34.5% to 35.6% (Ali et al., 2007), which agreed with this study. Muhlisin et al. (2013) also reported that no significant difference was found in cooking loss of breast meats between KND and commercial meat-type ducks. On the other hand, the WHC of breast meat from KND was significantly higher than the corresponding part in commercial breeds, which agrees with the present result. The WHC is important in raw meat and further processed meat products. Higher WHC affects sensory characteristics, as well as meat functionality. In previous study, the taste attributes of the cooked breast from KND scored higher than that from commercial meat-type ducks, according to the sensory evaluation by panels (Muhlisin et al., 2013).

Fatty acid composition and amino acid content

The fatty acid compositions of breast meats from both ducks are shown in Table 5. The palmitic acid (C16:0), stearic acid (C18:0), oleic acid (C18:1 ω9), linoleic acid (C18:2 ω6) and arachidonic acid (C20:4 ω6) were predominant fatty acids in breast meat from both breeds. The breast meat from KND contained more linoleic acid (p<0.05), α-linolenic acid (C18:3 ω3) and total polyunsaturated fatty acids and less (p<0.05) oleic acid and total monounsaturated fatty acids. In the case of Spanish wild ducks, palmitic acid, stearic acid, oleic acid, and arachidonic acid were the predominant fatty acids of breast meat (Cobos et al., 2000). The breast meat from KND had more total ω6 fatty acids and total polyunsaturated fatty acids than commercial meat-type ducks fed the same experimental diets (Muhlisin et al., 2013). The profile of dietary fats was reflected in the fatty acid composition of various tissues in avian species (An et al., 1997). In this study, both breeds were provided with the same starter and grower diets, and thus some important differences observed in the fatty acid profiles were due to the genotype. Duck meat is high in polyunsaturated fatty acids, especially linoleic acid (Farchat and Chavez, 2000). It is well known that dietary intake of polyunsaturated fatty acids is effective in lowering blood lipids levels (Grundy and Denke, 1990). The consumption of KND meat enriched with more polyunsaturated fatty acids will represent a better contribution to human diet and is more profitable than other animal products with respect to provision of fatty acids.

The contents of amino acid of breast meats from both breeds are shown in Table 6. The breast meat from KND contained more leucine, methionine, phenylalanine and tyrosine (p<0.05), although there were no significant differences in other amino acids. The minimal differences were observed in amino acid contents between both genotype. Because there is little available information on the amino acid content of KND, the interpretation of present results was difficult. Heo et al. (2013) reported that the contents of essential amino acid in KND meat increased with the elapse of rearing period. Further studies are required to clarify the distinction of amino acid composition between KND and commercial meat-type ducks.

In this study, different genotypes of ducks were reared to produce meats under identical feeding and rearing conditions. To avoid sex and slaughtering effects, we reared only males and slaughtered both ducks with usual slaughter weights. In conclusion, there were considerable differences between both genotype in several indices related to carcass characteristics and breast meat quality. At similar slaughter weights, the breast meat of 56 d-old KDN showed better quality in terms of WHC and fatty acid profiles compared with that of 42 d-old commercial meat-type ducks raised under the identical feeding and rearing conditions.

ACKNOWLEDGMENTS

This research was supported by a grant from National Institute of Animal Science, RDA, Korea.