Prediction equations for digestible and metabolizable energy concentrations in feed ingredients and diets for pigs based on chemical composition

Article information

Abstract

Objective

The objectives were to develop prediction equations for digestible energy (DE) and metabolizable energy (ME) of feed ingredients and diets for pigs based on chemical composition and to evaluate the accuracy of the equations using in vivo data.

Methods

A total of 734 data points from 81 experiments were employed to develop prediction equations for DE and ME in feed ingredients and diets. The CORR procedure of SAS was used to determine correlation coefficients between chemical components and energy concentrations and the REG procedure was used to generate prediction equations. Developed equations were tested for the accuracy according to the regression analysis using in vivo data.

Results

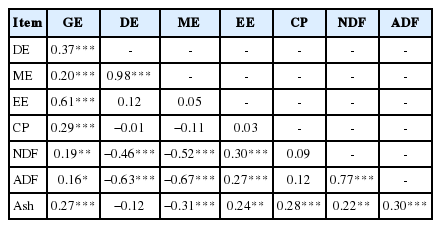

The DE and ME in feed ingredients and diets were most negatively correlated with acid detergent fiber or neutral detergent fiber (NDF; r = −0.46 to r = −0.67; p<0.05). Three prediction equations for feed ingredients reflected in vivo data well as follows: DE = 728+ 0.76×gross energy (GE)−25.18×NDF (R2 = 0.64); ME = 965+0.66×GE−24.62×NDF (R2 = 0.60); ME = 1,133+0.65×GE−29.05×ash−23.17×NDF (R2 = 0.67).

Conclusion

In conclusion, the equations suggested in the current study would predict energy concentration in feed ingredients and diets.

INTRODUCTION

Energy is known to be one of the most expensive nutritional components in animal feeds. Available energy of feeds can be partitioned into digestible energy (DE), metabolizable energy (ME), and net energy subtracting energy losses from gross energy (GE) [1]. However, net energy is less widely used compared with DE and ME due to difficulties of its determination and relatively large variations [2]. To obtain energy concentrations of feed ingredients and diets, metabolism experiments are required to collect feces and urine through restriction of physical activity of animals. However, as in vivo experiments are time–consuming and costly, prediction equations based on chemical components have been regarded as an alternative method for obtaining DE and ME of feeds [3].

Prediction equations for DE or ME for pigs have been developed for specific feed ingredients [4–6] and diets [3,7,8]. However, available equations for predicting energy concentrations in the literature are not applicable or risky in many cases. For example, some equations can be applied only to specific ingredients and others have a relatively narrow range of dietary chemical compositions. Inappropriate uses of these equations are susceptible to extrapolation bias [9,10]. To solve these problems, Choi et al [11] developed equations for DE in feed ingredients and diets for growing pigs and these equations were shown to be more accurate than previously published equations. However, Choi et al [11] provided equations only for DE but not ME. Therefore, the objectives of this study were to develop widely applicable prediction equations for DE and ME in feed ingredients and diets for pigs based on chemical components and to validate these equations using data from in vivo experiments.

MATERIALS AND METHODS

Data collection

A total of 734 data points from 81 studies that determined DE or ME were employed to develop equations for energy concentrations in feed ingredients and diets for pigs. The database consisted of chemical compositions and energy concentrations of feed ingredients and diets used in the experiments. Energy contents were expressed in kcal/kg dry matter (DM) and other variables were in % DM. When chemical components of feed ingredients or diets were not provided in a paper, chemical components were calculated by multiplying the inclusion rate of each ingredient by values provided in Sauvant et al [12] and NRC [1].

Statistical analysis

Correlation coefficients between chemical components and energy concentrations were determined by the CORR procedure of SAS (SAS Inst. Inc., Cary, NC, USA). Prediction equations for DE and ME were developed by the REG procedure. A coefficient of determination was an indicator to define the best fit equations.

The alpha level used for determining statistical significance was 0.05. The accuracy of prediction equations for energy concentrations was assessed by regressing the determined values of data from in vivo experiments [13–18] minus the predicted values for energy concentrations on the predicted values centered to the mean [19]. These data had not been used in developing prediction equations. To validate prediction equations for energy concentrations, only data corresponding to the range of chemical components used for equations in the current study were employed.

RESULTS AND DISCUSSION

Both of index method and total collection method are used for determining DE in feed ingredients and diets in pigs. In the present work, the experiments that used the index method were excluded. The reason for excluding data from the index method was that the indigestible index method may potentially underestimate nutrient digestibility due to low index recovery [20].

Feed ingredients had a wider range and greater variations of chemical components compared with diets (Table 1). The range of chemical composition of feed ingredients in the current study was wider than that of the previous studies [6,8,11], which is desirable for establishing prediction equations. The range of dietary chemical components of diets in the present work was wider than that in the work by Noblet and Perez [3], but maximum ash, crude protein, and neutral detergent fiber (NDF) contents were less than those of previous studies [7,8].

The variability of chemical components in feed ingredients and diets in the database (dry matter basis)

The DE and ME in feed ingredients and diets were correlated most negatively with acid detergent fiber (ADF) and NDF representing dietary fiber (r = −0.46 to r = −0.67; Tables 2, 3). The negative correlations between dietary fibers and available energy are in good agreement with previous studies where dietary fiber was the best predictor [3,7,8,11]. This is because dietary fiber decreases energy digestibility of other nutrients, and the digestibility of fiber itself is relatively less compared with starch, proteins, and lipids [7]. Dietary fiber can be categorized into crude fiber, ADF, NDF, total dietary fiber (TDF), insoluble dietary fiber, and soluble dietary fiber based on fiber analysis procedures [1]. In some previous studies, TDF was the most accurate independent variable to predict DE in corn byproducts among various dietary fibers [21,22]. As TDF includes β-glucans unlike other dietary fibers, theoretically, TDF provides an accurate estimate of dietary fiber [1]. However, a recent meta-analysis study indicated that dietary fiber analyzed by detergent fiber procedure showed a greater accuracy in predicting DE in feed ingredients and diets compared with TDF, insoluble dietary fiber, and soluble dietary fiber [11]. For this reason, the NDF and ADF were used to represent dietary fiber when developing equations in the current study.

Ash was also regarded as a potential independent variable for estimating DE and ME in feed ingredients and diets in the present work. Generally, energy concentrations in ingredients and diets decrease as ash concentration increases due to the lack of GE in ash [3]. In the current study, ash was negatively correlated with GE (r = −0.25), DE (r = −0.33), and ME (r = −0.45) in feed ingredients and was used for predicting DE and ME in several equations (Eq. 3, 5, 7, 8, and 12 to 17). In contrast to feed ingredients, ash was not included in the equations for predicting DE and ME in diets, which is likely due to the relatively narrow range of ash contents in diets (2.3% to 11.7%) compared with feed ingredients (0.2% to 46.2%).

Based on coefficients of determination, prediction equations for DE and ME in feed ingredients and diets were developed (Tables 4, 5). Equations with less than 0.5 of coefficient of determination were excluded. Some variables were highly correlated each other resulting in a decrease of the validity of regression coefficients as predictors [7]. For this reason, ADF and NDF were not included in the equation as independent variables as well as ether extract and GE.

In vivo experiments for testing the accuracy of the present equations were conducted in our laboratory and experimental conditions were kept constant among experiments (e.g., chemical analysis, environment and facilities, experimental procedures, and genetic strains of pigs). The DE or ME obtained from in vivo experiments was plotted against the DE or ME calculated using the equations developed in the present work. The intercept and slope generated by mean-centered regression representing a mean bias and linear bias, respectively, can be used as indicators of accuracy [23]. The mean bias and linear bias represent the difference between the average of measured and predicted energy values and the consistency of prediction error across the range of data, respectively. Based on the regression analyses, the slope and intercept were not different from 0 when validating Eq. 2, 11, and 12 (Tables 4, 5), which indicates that these equations accurately estimates in vivo DE and ME data employed in the present work.

Compared with prediction models for DE or ME in the literature, the present equations showed lower coefficients of determination and greater root mean squares of error. One possible reason is that experiments used to establish equations in the current study were conducted by various experimental stations. Experimental conditions may differ among institutions and these factors may cause variations. Particularly for chemical analysis, statistically significant difference may occur among analyzed values even though each station follows the same methods of chemical analysis [24]. In contrast to the current study, factors aforementioned were relatively controlled in previous modeling studies because most of metabolism experiments and chemical analysis were conducted in their own laboratories [3,6,25]. Another possible reason is that most of data used for establishing equations in the current study were derived from energy evaluation of feed ingredients. To evaluate available energy concentration in a feed ingredient precisely, the proportion of a target feedstuff is high which leads to an impractical diet formulation. In contrast, most diets fed to pigs to derive equations in previous studies [3,26] were corn- or wheat-based diets where the proportion of non-conventional feed ingredients was low. In addition, while previous equations for feed ingredients were applicable for specific feed ingredients such as animal byproduct, corn coproduct, and wheat [6,21,27], the equations developed in the present work were established based on various types of feed ingredients.

Despite these problems, the equations suggested in the current study are meaningful because most of data used for developing equations were derived from the recent studies. A great number of recent observations employed in the present work compared with previous studies should also be noted [3,7,25]. Furthermore, independent variables in equations consisted of commonly analyzed components in laboratories and equations were based on various combinations of chemical components.

CONCLUSION

Based on chemical compositions, energy concentrations in feed ingredients and diets can be fairly accurately estimated using the prediction equations proposed in this study. Further studies are warranted to develop prediction equations for net energy.

Notes

CONFLICT OF INTEREST

We certify that there is no conflict of interest with any financial organization regarding the material discussed in the manuscript.